Which method is the best for processing soybean oil?

FAQ / Chat on line / Give me a price / Date:January 14, 2025

Soybean oil is one of the most important edible oils in the world, and its processing process plays a crucial role in improving oil quality and yield. For the common methods for processing soybean oil--the pressing method and the solvent extraction method. Which method is the best for processing soybean oil needs to be decided according to the market orientation of the oil plant, the plant size and other circumstances.

The traditional pressing method

The traditional pressing of soybean oil involves mechanical pressing. Soybeans are first cleaned to remove impurities such as dirt, stones, and damaged beans. Then, the soybeans are usually heated to a certain temperature to make the oil more easily extracted. After that, the heated soybeans are put into a press, and through high - pressure squeezing, the oil is forced out of the soybean cells. The remaining solid material is called soybean meal.

Advantages:

Natural and pure: The oil obtained through pressing is considered more natural as it does not involve the use of chemical solvents. This makes it a preferred choice for consumers who are concerned about chemical residues.

Nutritional retention: It generally retains more of the natural antioxidants and other beneficial components present in soybeans.

Disadvantages:

Low yield: The pressing method usually has a relatively low oil yield. A significant amount of oil may still remain in the soybean meal after pressing, which means that more soybeans are needed to obtain a certain quantity of oil compared to other methods.

Higher cost: Due to the lower yield and the relatively complex mechanical equipment required for pressing, the cost of production can be higher. This may lead to a higher price for the final product in the market.

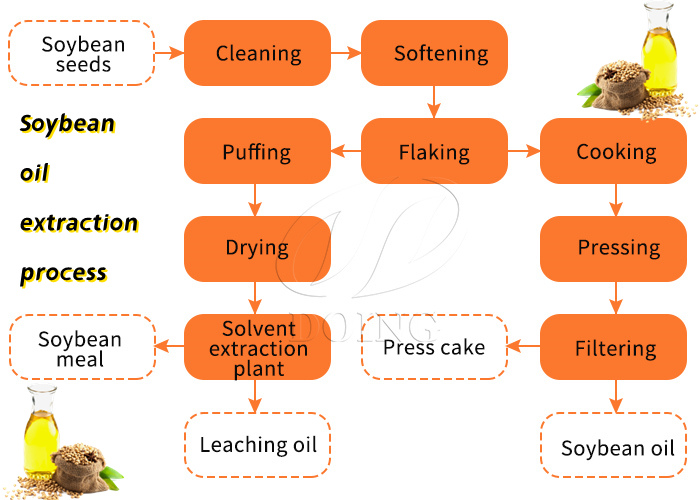

Soybean oil extraction process

Soybean oil extraction process

The solvent extraction method

Solvent extraction is a more modern and efficient method. Commonly, n-hexane is used as a solvent. The soybeans are first crushed and flaked to increase the surface area for better contact with the solvent. The flaked soybeans are then soaked in n-hexane, which dissolves the oil. After extraction, the solvent - oil mixture is separated from the solid residue. The solvent is then evaporated and recovered for reuse, and the remaining oil is further refined.

Advantages:

High Yield: This method can extract a much larger percentage of oil from soybeans. It can extract up to 95 - 99% of the available oil, which is significantly higher than the yield of the pressing method. This means that fewer soybeans are needed to produce a given amount of oil, making it more cost - effective in terms of raw material usage.

Economical: Because of the high yield and the relatively efficient process, the solvent extraction method is more economical on a large - scale production basis. The cost of production per unit of oil is usually lower, which allows for more competitive pricing in the market.

Disadvantages:

Nutrient Loss: The extraction process with solvents may lead to some loss of heat - sensitive nutrients.

Using solvent extraction process to make soybean oil

Using solvent extraction process to make soybean oil

If the focus is on the highest quality and a more natural product with a rich flavor and better - preserved nutrients, the traditional pressing method may be the best method for processing soybean oil. However, with strict quality control, the solvent - extracted oil can also meet high - quality standards, especially when it comes to the removal of impurities and the achievement of a consistent product. From an economic and yield perspective, the solvent extraction method is more favorable for large - scale industrial production. It allows for efficient use of raw materials and lower production costs. If the production is aimed at a niche market that values natural and artisanal products, the pressing method is a good option. For large - scale commercial production to meet the demands of a wide range of consumers and for use in various food - processing industries, the solvent extraction method, with proper safety and quality controls, may be the best method for processing soybean oil.

Henan Glory is engaged in the design and manufacturing of soybean oil processing equipment, selling directly at factory prices. It can provide soybean oil processing equipment with different processing capacities and can customize equipment of different models and processing capacities for customers. If you want to learn more about our equipment or the best method for processing soybean oil, please feel free to contact us, and we will be happy to serve you!

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line