How to choose oil press?

FAQ / Chat on line / Give me a price / Date:January 10, 2025

Choosing the right oil press for oil production involves considering several factors to ensure optimal efficiency, oil extraction, and longevity of the equipment. The right oil press will depend on the scale of your operation, the type of oil you're extracting, your budget, and the level of automation you desire.

How to choose oil press? Here’s a step-by-step guide to help you choose the right oil press for your oil extraction needs:

1. Determine the scale of production

Small scale (home or local use)

If you’re producing oil for personal use or small-scale local sale, you might prefer a manual or small-sized hydraulic press or screw press. These are typically more affordable and can process smaller quantities of raw material per hour.

Medium scale (small to medium enterprises)

For moderate production volumes, you’ll need a semi-automatic screw press. These presses can process a higher volume of raw material and are more efficient than smaller models. They may also include features like automatic feeding and oil filtration systems.

Large scale (industrial use)

For industrial-scale operations, you’ll need an automatic screw press or a continuous screw press. These presses can handle large volumes of raw materials continuously and are typically equipped with automated systems for feeding, pressing, oil separation, and even cake extraction.

Different cooking oil press equipment

Different cooking oil press equipment

2. Type of oil press

There are two primary types of oil presses: cold presses and hot presses. Cold Press involves extracting oil without heating the seeds, which helps preserve the natural nutrients and flavor of the oil. It is typically used for oils that are more sensitive to heat, such as olive oil, sunflower oil, or almond oil. In hot pressing, the seeds is heated to soften it before being pressed. The heat helps to increase oil yield and facilitates the extraction of more oil.

3. Pressing mechanism

Screw Press is the most common type of oil press used in oil production. It uses a rotating screw to press the oil out of the raw material. It’s oil extraction rate is high, even with higher moisture content in the material. But it Requires regular maintenance due to wear and tear on the screw and other moving parts.

Using hydraulic pressure to extract oil from the material. The material is placed in a chamber, and pressure is applied to extract the oil. It Produces high-quality oil with minimal heat, preserving nutrients, lower energy consumption and less mechanical wear. But it is typically slower than screw presses and may not be suitable for high-volume production like palm oil.

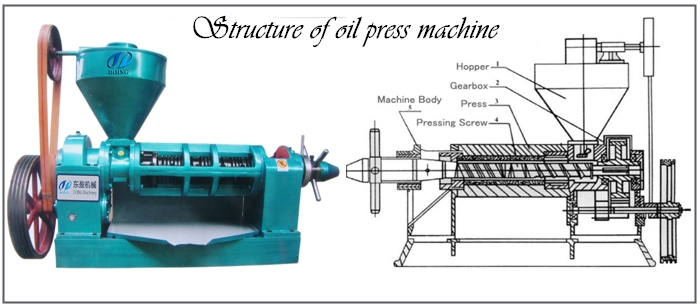

Structure of oil press equipment

Structure of oil press equipment

4. Capacity and throughput

The capacity of the oil press refers to how much raw material it can process per hour. Choose a press that matches your expected production volume. Having a higher capacity press than needed can lead to unnecessary power consumption, while a lower capacity press may limit production efficiency.

5. Material quality & durability

Check the material quality of the oil press. Since oil extraction involves high pressures and temperatures, the press should be made of high-quality, durable materials such as stainless steel to withstand wear and corrosion. Look for presses with high-strength alloy steel or stainless steel components for critical parts like the screw and the press cage. For the frame and other structural parts, carbon steel or cast iron may be sufficient, depending on the scale.

6. Maintenance and spare parts availability

Like all machinery, oil presses require regular maintenance. It's important to choose a model that is easy to maintain and has readily available spare parts. Look for reputable brands or manufacturers with a strong customer service network. Ensure that spare parts, like screws, press cages, and filters, are easy to replace and cost-effective.

Oil press needs to be chosen according to the oil and specific processing capacity, if you have questions about which type of oil press to choose, welcome to call Henan Glory, we will arrange professional engineers to recommend a suitable oil press for you. Ultimately, choose a press that meets your production goals, budget, and operational needs.

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line