What is the technology of groundnut oil production?

FAQ / Chat on line / Give me a price / Date:January 11, 2020

The technology of groundnut oil production refers to the methods of extracting crude groundnut oil from groundnut seeds or refining crude groundnut oil into product oil. In this article, I will introduce the standard technology of groundnut oil production in large scale oil mill factory. Hope it can help you understand.

Part 1 Crude groundnut oil processing technology

The methods of extracting crude groundnut oil from groundnut seeds can be divided into two kinds: pretreatment+press method and pretreatment+pre-press+solvent extraction method. Because the pretreatment part is the same, I will firstly introduce this part.

1. Groundnut seed pretreatment process of groundnut oil production

The equipment used in groundnut seed pretreatment process contains cleaning machine, husking machine, flaking machine, cooking machine.

The pretreatment machines used in groundnut oil production

The pretreatment machines used in groundnut oil production

The main function of these groundnut seed pretreatment equipment:

a.Cleaning machine: used to remove the impurities in groundnut seeds, such as dust, straw, stone, iron, etc, which can prevent the subsequent equipment from wear and tear seriously.

b. Husking machine: used to remove the shell of groundnut, which can decrease the oil residual.

c. Flaking machine: used to extrude the groundnut seed into sheet, which can improve the following process efficiency.

d. Cooking machine: used to adjust the temperature and moisture of groundnut seeds sheet, which can increase the oil yield.

2.Groundnut oil press process of groundnut oil production

Physical press technology is suitable for small scale or medium scale groundnut oil production, usually 1-30 tons per day. The common used groundnut oil press machine has four kinds: hydraulic oil presser, integrated oil presser, single screw oil presser and large scale oil presser with auxiliary frying pan.

Four kinds of groundnut oil press machine

Four kinds of groundnut oil press machine

In 10-30tpd groundnut oil mill factory, the single screw oil presser and large scale oil presser with auxiliary frying pan are usually used.

3.Groundnut oil pre-press and solvent extraction process of groundnut oil production

Pre-press+solvent extraction method is the best choice for large scale groundnut oil mill factory, more than 30 tons per day. Why? Because groundnut seeds has high oil content, only using press method, there will be large amount of oil residual in groundnut cake. To avoid the waste, large scale groundnut oil mill factory often use pre-press machine to get part of groundnut oil from groundnut seeds, and then use solvent extraction method to get other part of groundnut oil from the groundnut cake. The most important is that the residual oil rate can be lower than 1% after solvent extraction process.

Four systems in groundnut oil solvent extraction plant

Four systems in groundnut oil solvent extraction plant

The main functions of groundnut oil solvent extraction equipment

a. Solvent pumps: continuously spray solvent onto groundnut cake in the rotocel extractor.

b. Rotocel extractor: spray and soak the groundnut cake with solvent so that oil fats can be dissolved in solvent to form mixed oil. After processing, you can get wet meal and mixed oil.

c. DTDC tower: used to separate the solvent from the wet meal. You can get dry meal which can be processed into animal feed.

d. 1st evaporator, 2nd evaporator & stripping tower: to separate the solvent from mixed oil, and you will get groundnut oil and solvent.

e. Condenser: used to cool the solvent gas separated from the wet meal and mixed oil for recycling and reuse.

Part 2 Groundnut oil refining technology

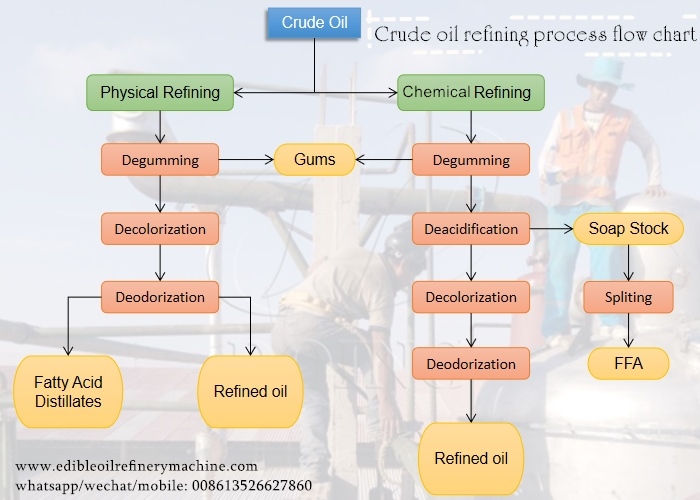

The method of refining crude groundnut oil into product oil has two kinds: chemical refining method and physical refining method. And based on the continuous mode, the groundnut oil refining equipment has three types: batch type, semi-continuous and full-continuous type.

Physical refining and chemical refining process flow chart in groundnut oil production

Physical refining and chemical refining process flow chart in groundnut oil production

The difference between chemical refining method and physical refining method:

Actually, chemical refining method and physical refining method is distinguished according to different deacidification methods. Deacidification method has two kinds: acid-alkali neutralization deacidification method and distillation deacidification method. About how to choose suitable method to refining groundnut oil, it depends on the acid value of your crude groundnut oil. Generally, if the acid value of your crude groundnut oil is very high, our engineers will recommend you to use physical refining method.

As for how to choose the type of groundnut oil refining equipment, it depends on your input capacity, budget, product oil requirement, etc. If you want to build the groundnut oil refinery plant, discussing the detailed requirement with engineers is very importance for you. Our Henan Doing Company has very rich experience to help you design the groundnut oil refining process, plant design chart, suitable equipment, etc.

These are the introduction of the technology of groundnut oil production, which are all based on our DOING engineers' experience. DOING Company is professional groundnut oil production machine manufacturer in China. If you need, welcome to contact us!

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line