The development of cooking oil production technology

FAQ / Chat on line / Give me a price / Date:January 28, 2021

1. The brief introduction of cooking oil and its use

Cooking oil is extracted from different kinds of oil seeds, such as groundnut, soybean, sunflower seeds, rice bran, corn germ, palm fruit, palm kernel, etc, and then through refining process to get. Except for cooking in daily life, cooking oil is sometimes added during the preparation of processed foods.

Common oil seeds used to process cooking oil

Common oil seeds used to process cooking oil

2. The beginning of cooking oil production technology

Thousands of years ago, people in many areas began to try to process cooking oil from the oil seeds they had.

a. Early people learned to use the sun, fire to heat the oil seeds until the oil could be collected.

b. 2000 B.C. ago, the Chinese and Japanese had researched the method to produce soybean oil.

c. When 3000 B.C, southern Europeans had begun to produce olive oil.

d. In Mexico and North America, people roasted the peanuts and sunflower seeds, beat the roasted peanuts and sunflower seeds into a paste, and then boil the paste in water. At last, the oil will be kept afloat to the water surface and then be skimmed off.

e. Africans grated and beat palm fruits and coconut meat and then boiled the resulting pulp, skimming the hot oil off the water.

The traditional palm oil production technology in Africa

The traditional palm oil production technology in Africa

3. The development of cooking oil production technology

The first efforts to increase the oil output were undertaken respectively in China, Egypt, Greece, Rome, etc. People used a spherical or conical stone mortar and pestle, vertical or horizontal millstones, or their feet to crush the oil seed, so as to increase their available surface area. And then the ground materials would be subsequently placed in sieves such as shallow, flat wicker baskets that were stacked, sometimes as many as 50m high. The materials was then pressed using lever or wedge presses.

Later, the Greeks and Romans improved this process by introducing edge runners to grind the oil seeds and a winch or screw to operate the lever press. Their method was used throughout the Middle Ages.

Then, it was time to upgrade the oil press. In the 1600s, Holland invented a stamper press. In 1750, English engineer John Smeaton invented a roll mill to crush vegetable matter more efficiently, and Joseph Bramah invented the hydraulic press to extract oil more efficiently. In 1876, in the United States, V. D. Anderson invented the first improved screw press. His screw press continuously operated a cage press. When the oil seed was placed in the screw press, the resultant oil drained out of slots in the side.

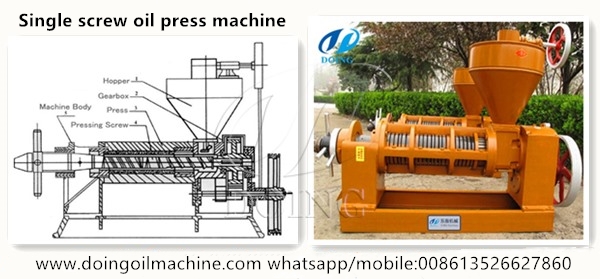

Screw oil press machine and its inner structure

Screw oil press machine and its inner structure

Next, it is the improvements of solvent extracting technology in cooking oil production. In 1856, Deiss of England obtained the first patent for extraction of oil using solvents, following experiments by Jesse Fisher in 1843. At first, solvents such as benzene were pumped through the material and drained through false perforated bottoms. Later, Bollman and Hildebrandt of Germany independently developed continuous systems that sprayed the material with solvent. Both methods were eventually improved, and today solvent extraction is standard in the vegetable oil industry.

4. The formation of modern cooking oil production technology

With the dvelopment of cooking oil production technology, modern cooking oil production technology has been very mature. The complete cooking oil production process involves cleaning the seeds, grinding them, roasting them, pressing, and extrading the oil from them. In extracting, a volatile hydrocarbon such as hexane is used as a solvent. After extracting, the oil is refined through degumming, deacidification, decolorization, deodorization, dewaxing or fractionation processes, and then the oil is filtered, and ready for packaging.

Besides, the oil yield rate becomes higher and higher. The very earliest methods of pressing the oil seeds probably obtained, at best, 10 percent of the oil available. However, by more modern methods--solvent extraction technology, the residual oil rate can be less than 1%.

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line