Tips for buying cooking oil refining equipment

FAQ / Chat on line / Give me a price / Date:March 14, 2025

The purpose of cooking oil refining is to remove impurities from crude cooking oil through technical means in order to meet a certain standard and ensure the health of the cooking oil. When buying cooking oil refining equipment, it's essential to consider various factors to ensure you're investing in the right equipment for your needs. Here are some key tips for buying cooking oil refining equipment to help guide your purchase.

1. Understand Your Refining Needs

Capacity: Determine the amount of oil you plan to refine daily or annually. The equipment should match your production scale. Small-scale refining typically requires less capacity than large-scale industrial operations.

Type of Oil: Different oils require different cooking oil refining processes. Make sure the equipment is compatible with the type of oil you intend to refine.

2. Quality and Reliability of the Equipment

Durability: Choose equipment made from high-quality materials, such as stainless steel, for longevity and easy cleaning.

Brand Reputation: Opt for equipment from reputable manufacturers with a track record of reliability and good customer service.

Compliance: Ensure that the cooking oil refining equipment complies with local regulations and safety standards.

3. Automation and Control Systems

Look for cooking oil refining equipment with modern automation features that can reduce manual labor and improve consistency. Control systems should be user-friendly, with the ability to monitor and adjust parameters (temperature, pressure, etc.) to optimize the cooking oil refining process.

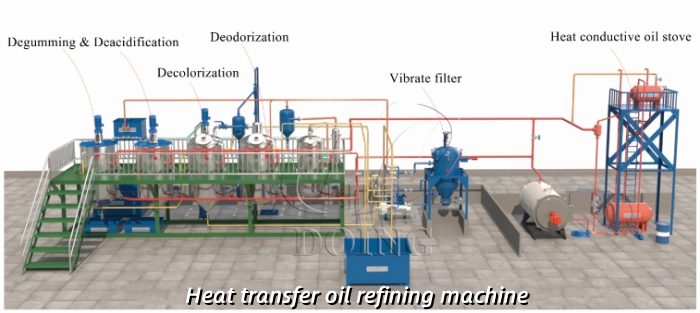

Cooking oil refining equipment

Cooking oil refining equipment

4. Energy Efficiency

Cooking oil refining can be an energy-intensive process. Choose energy-efficient equipment that minimizes power consumption and reduces operating costs over time.

5. Space and Installation Requirements

Assess the available space in your facility to ensure the equipment will fit comfortably. Make sure the manufacturer provides a detailed installation plan, and check whether they offer on-site installation and support.

6. Cost Considerations

Initial Cost: Compare prices from different suppliers, but don’t just focus on the lowest price. Sometimes, a higher upfront investment may be justified by better quality or efficiency.

Operating Costs: Factor in ongoing costs like energy consumption, maintenance, and spare parts availability.

Return on Investment (ROI): Consider how the cooking oil refining equipment will impact your overall production efficiency and profitability in the long term.

7. Maintenance and Support

Opt for cooking oil refining equipment that is easy to maintain with readily available spare parts. Some manufacturers also offer comprehensive maintenance packages or training for your team.

Check if the manufacturer provides a warranty and after-sales support to ensure the equipment runs smoothly post-purchase.

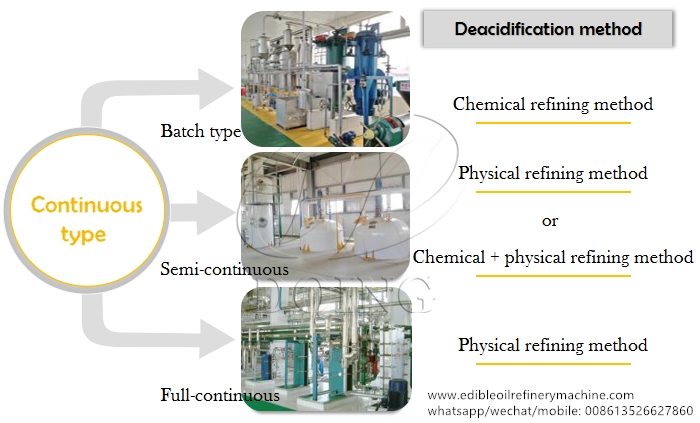

Different types of refining method in edible oil refining process

Different types of refining method in edible oil refining process

8. Technology and Innovation

Look for advancements in refining technology, such as continuous refining systems, which are more efficient and less labor-intensive than batch systems. Technology upgrades can improve product quality and reduce waste.

9. Environmental Impact

Ensure the cooking oil refining equipment meets environmental standards. For instance, check if the refining process produces minimal waste or emissions, or if there are mechanisms to handle waste products efficiently.

10. Customer Reviews and Testimonials

Before buying cooking oil refining equipment, research reviews and testimonials from other buyers to gauge the reliability and performance of the equipment. Real-world experiences can provide valuable insights into its efficiency and durability.

11. Supplier and Manufacturer Support

Make sure the supplier offers good pre- and post-sales support. They should assist with equipment setup, training, and troubleshooting. Some suppliers also offer custom solutions to meet specific needs.

12. Regulatory Compliance

Ensure that the cooking oil refining equipment meets the standards and regulations for food safety in your region, such as certifications from food safety organizations.

Above are all the tips for buying cooking oil refining equipment. By carefully considering these factors, you can buy cooking oil refining equipment that meets your production goals, quality requirements, and long-term operational needs. We are a professional manufacturer of cooking oil processing equipment. Our equipment is suitable for a variety of raw materials, such as sunflower seed, soybean, peanut, cottonseed, rice bran, rapeseed, palm fruit, palm kernel, and so on. The cooking oil refining process is also a professional technology we can provide. If you are interested in refining equipment, please contact us for a free quotation and consultation.

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line