Why is there powder in solvent extraction soybean oil? How to solve it?

FAQ / Chat on line / Give me a price / Date:March 12, 2025

The solvent extraction method for producing soybean oil has high oil extraction efficiency and lower residual oil rate. However, some soybean oil processing manufacturers have found that some powder will remain in the extracted soybean oil during the extraction process. Why is there powder in solvent extraction soybean oil? The reason is mainly due to the oil properties of soybeans, the equipment selection and whether the filtration is thorough. This article will introduce some solutions for solvent extraction soybean oil powder, such as configure softening equipment in the pretreatment stage, equip with complete soybean oil refining equipment, and maintain and operate equipment properly.

Reasons

1. Low Moisture and Oil Content in Soybeans: Soybeans are low in oil content, with an oil content of 16% to 20%, and also have relatively low water content after maturity. During the processes of crushing and flaking, more soybean powder is produced. Even with two to three hours of sufficient contact with the solvent, some powder will remain in the soybean oil solvent extraction process.

2. Improper Equipment Operation: If the extraction equipment is not properly adjusted or maintained, it may also lead to the presence of powder in the oil. For example, if the gap of the rolling mill is too small, it will cause excessive crushing of soybeans and generate more powder.

3. Incomplete Filtration: During the soybean oil solvent extraction process and subsequent oil treatment, if the filtration equipment or process is faulty, it is unable to completely remove the solid impurities and powder in the oil, resulting in powder remaining in the soybean oil.

Solutions

1. Configure Softening Equipment in the Pretreatment Stage

Choose the Appropriate Softening Pot: For example, vertical softening pots are simple in structure and relatively inexpensive, with a good water regulation effect. Having a large single-unit processing capacity, low power consumption, and no dead corners for materials. Through the softening pot, adjusting the water content and temperature of soybeans can increase their plasticity, thereby reducing the amount of powder produced during the subsequent crushing and flaking processes.

Optimize Softening Parameters: Strictly control the temperature and water content of the soybeans during the softening process, Which can make the rolled flakes have better elasticity and plasticity and solve the problem of powder in solvent extraction soybean oil.

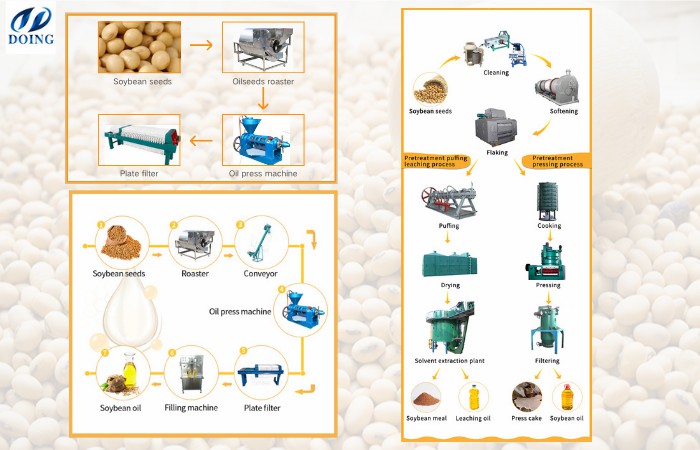

Soybean oil production line

Soybean oil production line

2. Equip with Complete Soybean Oil Refining Equipment

This is also a solution for solvent extraction soybean oil powder. Carry out Degumming, Deacidification, Decolorization and Deodorization: Add phosphoric acid, lye, decolorizing agents and other substances to the oil to make them react with colloidal impurities, acidic substances, pigments and other impurities in the oil, so as to remove these impurities. Degumming can remove phospholipids and other colloidal substances, deacidification can reduce the content of free fatty acids, decolorization can remove pigments, and deodorization can remove odor-causing small molecules in the oil under high-temperature and oxygen-free conditions.

Conduct Precision Filtration: Use leaf filters and other equipment to conduct precision filtration on the oil after degumming, deacidification, decolorization and deodorization, so as to fully filter out the generated impurities and some original soybean powder, and obtain clean solvent-extracted soybean oil.

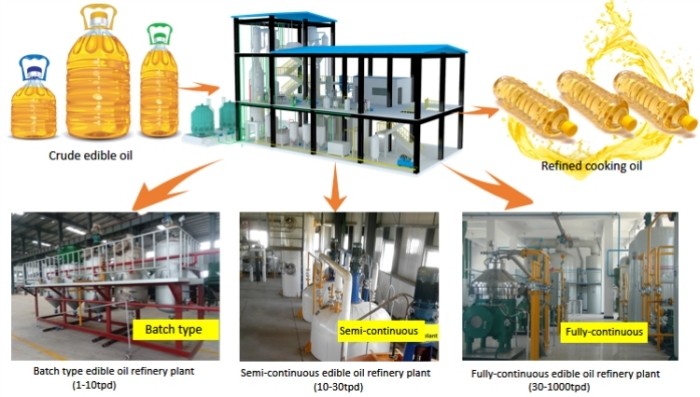

Henan Glory edible oil refining equipment

Henan Glory edible oil refining equipment

3. Maintain and Operate Equipment Properly

Regular Equipment Maintenance: Perform regular inspections and maintenance on extraction equipment, rolling mills, filters and other equipment to ensure their normal operation. Check and replace worn parts in a timely manner to avoid problems such as improper equipment operation causing excessive powder.

Standardize Operational Procedures: Operators should strictly follow the operating procedures, adjust the equipment parameters correctly, such as controlling the appropriate temperature, time and solvent ratio in the extraction process, and adjusting the rolling mill gap reasonably to avoid excessive crushing of soybeans, so as to solve the problem of powder in solvent extraction soybean oil.

The above solutions can effectively solve the problem of powder in solvent extraction soybean oil, improve the quality of solvent extraction soybean oil. Henan Glory has 13 years of experience in cooking oil processing equipment manufacturing, can provide you with customized equipment and project solutions, welcome to contact us to get your customized services.

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line