How to remove aflatoxin in peanut oil?

FAQ / Chat on line / Give me a price / Date:March 19, 2025

Aflatoxin is highly carcinogenic, and long-term excessive intake can cause serious damage to organs such as the liver and kidneys. Therefore, it is crucial to eliminate aflatoxin in peanut oil and protect the health of consumers. So, as a peanut oil producer, how to remove aflatoxin in peanut oil effectively?

Strict Control of Material Selection

To remove aflatoxin from peanut oil, we must first start from the source. Aflatoxin is mainly due to poor storage of peanut raw materials and peanuts to send mildew, keep peanuts stored in a dry, ventilated environment to avoid mildew. Henan Glory company adheres to the selection of healthy and pollution-free peanut raw materials to ensure that every peanut meets strict quality requirements during the growth and storage process. Through strict screening, contaminated peanuts are prevented from entering the production line.

Peanut Oil Refining

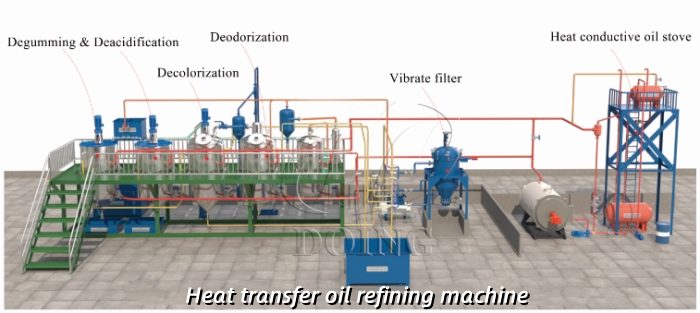

Temperature control plays a vital role in the production of peanut oil. Aflatoxin will be destroyed at high temperatures. Therefore, in the refining process of peanut oil, high-temperature detoxification technology is used to reduce the aflatoxin in peanut oil to a minimum through scientific heating temperature and time. Our production line uses sophisticated temperature control technology to ensure that every drop of peanut oil meets food safety standards.

Activated carbon adsorption is an effective method for removing aflatoxin in peanut oil. By adding a certain amount of activated carbon during the refining process of peanut oil, aflatoxin in the oil can be adsorbed and removed. During the refining process, we accurately control the amount of activated carbon added to ensure the purity of the peanut oil without affecting the flavor and nutritional content of the oil.

Cooking oil refining equipment

Cooking oil refining equipment

Ultraviolet Irradiation

The ultraviolet irradiation method uses ultraviolet rays to treat peanut oil, which can degrade the aflatoxin in it. This method is relatively simple to remove aflatoxin in peanut oil, and has little damage to other components in edible oil, with a removal rate of more than 94%. However, ultraviolet irradiation will increase the peroxide value and other indicators in the oil, affecting the quality of the edible oil. The ultraviolet aflatoxin degradation machines currently on the market apply this principle, but the degradation time of aflatoxin degradation machines is long and the oil output is slow, which often cannot meet the production needs of enterprises.

Regular Testing and Quality Control

In addition to technical means in the production process, a strict quality control system and regular testing are also important guarantees for removing aflatoxin in peanut oil. Our company regularly entrusts third-party testing agencies to test the aflatoxin content of products to ensure that each batch of peanut oil meets national food safety standards. Only through scientific testing can we guarantee consumers that the peanut oil they buy is safe and reliable.

Peanut oil production equipment

Peanut oil production equipment

For consumers, it is particularly important to choose peanut oil produced by regular manufacturers. Regular companies not only have strict production standards and quality control systems, but also use technical means to effectively remove aflatoxin in peanut oil to ensure consumer food safety. When purchasing, consumers should pay attention to the relevant test reports of the product to ensure that the peanut oil they purchase meets national food safety standards.

As an important edible oil in our daily life, the safety of peanut oil has always been a concern. Through advanced technical means, strict peanut oil production process and scientific quality management, we can effectively remove aflatoxin in peanut oil and provide consumers with safer and healthier edible oil.

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line