Is it better to press or extract soybean oil?

FAQ / Chat on line / Give me a price / Date:March 26, 2025

When it comes to producing high-quality soybean oil, the method of extraction plays a crucial role in determining the final product's quality, nutritional value, and flavor. Henan Glory specializes in providing state-of-the-art solutions for soybean oil production, helping our clients make informed decisions about whether to press or extract soybean oil. Is it better to press or extract soybean oil? Let’s explore the differences between these two methods and why choosing the right process matters for your business.

Pressing Method

Pressing is a traditional method of extracting oil from soybeans. This mechanical process involves applying high pressure to the soybeans to squeeze out the oil. There are two types of pressing: cold pressing and hot pressing.

1. Cold Pressing:

This soybean oil pressing method retains the natural flavor, color, and nutritional value of the oil, making it ideal for premium, health-conscious markets. Cold pressing is often preferred for producing organic or specialty oils, as it avoids the use of chemicals or high temperatures. However, cold pressing yields a lower quantity of oil compared to other methods, which can make it less cost-effective for large-scale production.

2. Hot Pressing:

By heating the soybeans before pressing, this soybean oil pressing method increases oil yield. The heat helps to release more oil from the soybean flakes, but it may slightly reduce the oil's nutritional content due to exposure to higher temperatures. Hot pressing is a good middle ground for businesses looking to balance yield and quality.

Advantages of Pressing:

Natural and Clean Process: No chemical solvents are used, making it a cleaner and more natural process.

Preserves Nutritional Value: Cold pressing, in particular, retains the oil's natural antioxidants, vitamins, and essential fatty acids.

Ideal for Specialty Markets: Perfect for producing organic, artisanal, or premium oils that cater to health-conscious consumers.

Disadvantages:

Low yield: The soybean oil pressing method usually has a relatively low oil yield. A significant amount of oil may still remain in the soybean meal after pressing, which means that more soybeans are needed to obtain a certain quantity of oil compared to other methods.

Higher cost: Due to the lower yield and the relatively complex mechanical equipment required for pressing, the cost of production can be higher. This may lead to a higher price for the final product in the market.

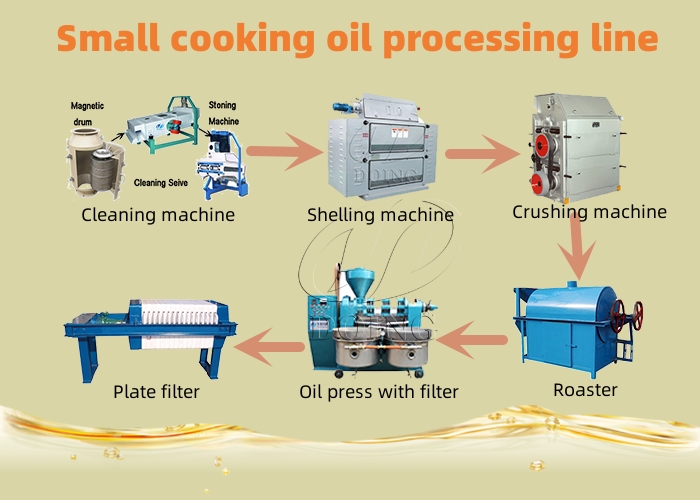

Soybean oil pressing production line

Soybean oil pressing production line

Solvent Extraction Method

Soybean oil solvent extraction method is a more modern and efficient method of obtaining soybean oil. This process uses chemical solvents, such as n-hexane, to dissolve the oil from the soybean flakes. After extraction, the solvent is removed, leaving behind pure soybean oil.

Advantages of Solvent Extraction:

Higher Oil Yield: Solvent extraction can recover up to 99% of the oil from soybeans, making it far more efficient than pressing.

Cost-Effective for Large-Scale Production: The high yield and lower production costs make it ideal for industrial-scale operations.

Versatility: Suitable for producing refined soybean oil, which is used in a wide range of food products, from cooking oils to margarine and processed foods.

Disadvantages of solvent extraction

1. High cost: The process of solvent extraction is relatively complicated, which requires professional equipment and technology, which increases the production cost. In addition, solvent extraction method has higher requirements for the production environment. The investment cost is higher than the pressed method.

2. Impact on the environment: Solvent extraction method requires a large amount of solvents, which may pollute the environment if not handled properly or recovered incompletely.

If the focus is on the highest quality and a more natural product with a rich flavor and better - preserved nutrients, the traditional soybean oil pressing method may be a better method for processing soybean oil. However, from an economic and yield perspective, the soybean oil solvent extraction method is more favorable for large - scale industrial production. It allows for efficient use of raw materials and lower production costs. For large - scale commercial production to meet the demands of a wide range of consumers and for use in various food - processing industries, the solvent extraction method, with proper safety and quality controls, may be a better method for processing soybean oil.

Soybean oil solvent extraction

Soybean oil solvent extraction

Above is the introduction of soybean oil pressing method and solvent extraction method. Whether soybean oil is better pressed or extracted is affected by the investment, the demand for soybean oil quality and the size of the plant. Henan Glory is engaged in the design and manufacturing of soybean oil processing equipment, selling directly at factory prices. It can provide soybean oil processing equipment with different processing capacities and can customize equipment of different models and processing capacities for customers. If you want to learn more about our equipment or the best method for processing soybean oil, please feel free to contact us, and we will be happy to serve you!

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line