The introduction of vertical stack cooker

FAQ / Chat on line / Give me a price / Date:April 15, 2025

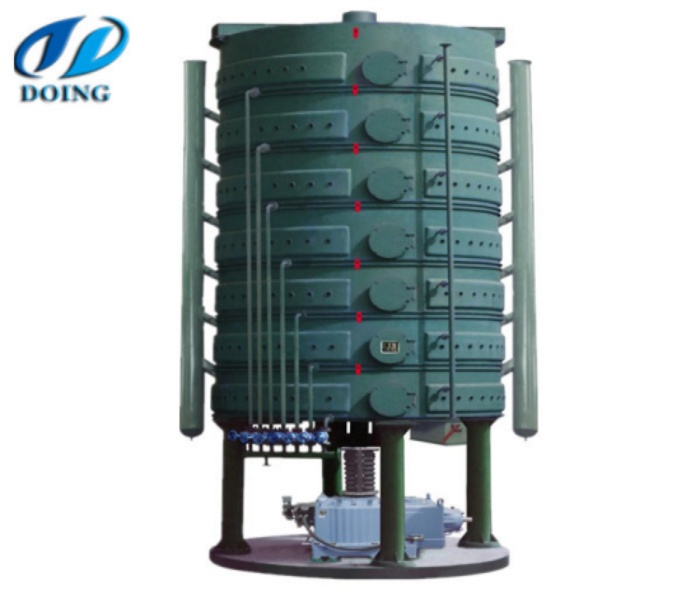

A vertical stack cooker is used for wetting and cooking the flakes from the flaking roll to meet the technological requirements of oil pressing or extracting, enhancing oil yield, and improving the quality of crude oil. Vertical stack cooker is used in large-scale oilseed processing. It is suitable for cooking the flakes of peanut, soybean, rapseed, sesame, cottonseed, camellia seed, sunflower seeds, copra, corn germ, etc. Vertical cookers can also be used as conditioners.The following is a brief introduction from five aspects: structural characteristics, classification, advantages, technical performance and application scenarios.

Structural Characteristics

Composition: Usually consists of a pot body and support feet. The pot body is a double - layer structure composed of an inner and outer hemispherical pot body, straight edge, and support. The middle interlayer is filled with steam for heating.

Types: They can be divided into vertical stack cookers with or without stirring devices according to process requirements. The stirring type can be further divided into ordinary stirring and scraping - side stirring types, which are suitable for pasty or sticky materials.

Classification

By Heating Method: There are electric - heated vertical stack cookers, steam - heated vertical stack cookers, and gas - heated vertical stack cookers.

By Material: They can be divided into all - stainless - steel vertical stack cookers, where both the inner and outer pot bodies are made of stainless steel, and ordinary vertical stack cookers, where the inner pot body is made of stainless steel and the outer pot body is made of carbon steel with anti - rust paint on the outside.

By Volume: Common volumes include 50L, 100L, 200L, 300L, 400L, 500L, 600L, 800L, and 1000L. Custom - made non - standard sizes are also available according to customer requirements.

Vertical stack cooker

Vertical stack cooker

Advantages

High Heating Efficiency: With a large heating area, the heat is evenly distributed, the liquid boiling time is short, and the heating temperature is easy to control. It can improve the production efficiency and product quality.

Good Sealing Performance: It can prevent steam leakage, ensure the safety of use, and reduce energy loss.

Easy to Operate and Clean: The structure is simple, and the operation is convenient. The stirring device can be disassembled and cleaned, which is easy to maintain the hygiene of the equipment.

Technical Performance

Stirring Device: For vertical stack cookers with a stirring device, the stirring paddle shaft is connected to the output shaft of the reducer through a loose sleeve, which is convenient for disassembly and cleaning. The stirring speed is generally 36r/min, and different stirring paddle forms can be selected according to customer requirements.

Support Feet Form: There are triangular pyramid - shaped and round - tube - shaped support feet.

Equipment Configuration: It is equipped with safety valves, pressure gauges, exhaust valves, steam inlets, outlets, etc., which can ensure the safe and stable operation of the equipment.

Application Scenarios

Vertical cooker is the main equipment to cook the oilseeds before pressing in the edible oil production line. Other cooking machines include rotary cooker, flat bottom cooker, and hot air roasting machine. Flakes are wet, heated, steamed, and cooked in the cooker to destroy the cellular structure, denature protein to make the oils agglomerate, change the plasticity, and reduce the vidcosity of the oils, which is favorate for pressing. The cooking effect has a directimpact on the smooth running of whole oil production process, and oil yield, and the quality of oil cake.

Vertical stack cooker is mainly often a necessary machine in oil seeds pretreatment process. No matter your oil mill is small scale or medium scale, increase the oil yield and improve the quality of oil must be that you want. So buy a set of vertical stack cooker to work with the oil presser is a good choice for you.

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line