Coconut oil processing machine

Oil press machine / Chat on line / Give me a price / Date:September 8, 2023

The coconut oil processing machine is mainly used to process copra into coconut oil, and mainly includes conveyor, crusher, flaking machine, cooker, coconut oil presses, filter, and filling machine.

Coconut oil processing machine

Coconut oil processing machine

A brief introduction to coconut oil processing machine and production process:

The coconut oil production process first requires the coconut to be pre-treated. The pre-processing process includes transportation and crushing of copra. It is then peeled and pressed to produce crude coconut oil. Finally, filter to obtain pure and nutritious coconut oil.

Coconut processing: 1. Transport the copra to the feed port 2. Crush the copra 3. Press the copra into thin flakes 4. Put the copra into a cooker to adjust the temperature and moisture 5. Press and dehydrate to obtain crude coconut oil 6. Filter the crude coconut oil 7. Pack and sell

Detailed introduction of coconut oil processing machine:

1. Copra conveying: The belt conveyor is mainly composed of a frame, a conveyor belt, a belt roller, a tensioning device, and a transmission device. Driven by the motor, the closed endless belt runs continuously through the friction between the belt and the driving drum, and sends the copra to the feeding port.

Copra Conveying Equipment

Copra Conveying Equipment

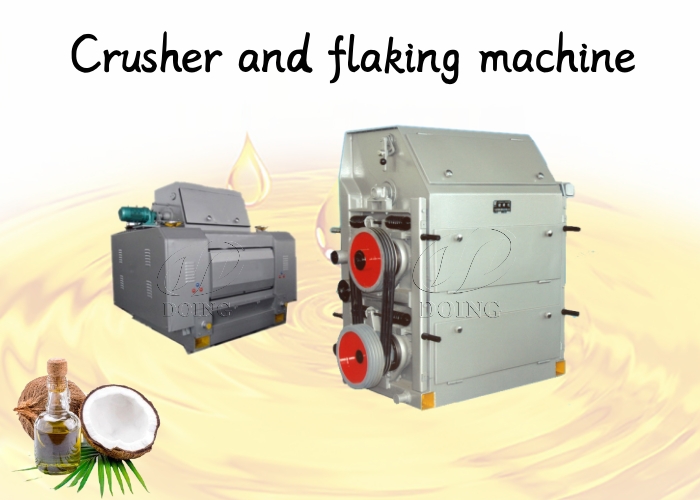

2. Crusher: Copra is a large piece of copra meat, and its size can be 180mm x 100mm x 6mm. The copra will be cut into small pieces by the crusher, which facilitates our embryo pressing, reduces wear on the machine, and increases the oil yield.

Crusher and flaking machine

Crusher and flaking machine

3. Flaking machine: Copra is too dry, too hard, and has low density. If the rolling distance is too small, the material will accumulate between the two rollers. Therefore, the peeling of copra is different from other oil materials, and the rolling distance is larger, about 3 to 4.5mm, to avoid high powdering, sticking rollers and non-smooth material discharge.

4. Cooker: In the processing of coconut oil, the cooker is used to cook the copra and adjust the temperature and moisture of the copra to achieve a better effect of squeezing edible oil. There are two types of cookers: horizontal and vertical. Customers can choose one of the two based on their factory design and area or other actual needs.

Cooker

Cooker

5. Coconut oil press: The main function of coconut oil press is to extract coconut oil from copra. According to different coconut oil processing capacity, there are three types of coconut oil press for people to choose, one is screw oil press, the other is fully automatic oil press, and automatic oil press is divided into with filter and without of the filter. Filter.

Coconut oil press

Coconut oil press

6. Filter: The filtration stage is generally equipped with a plate and frame filter or a leaf filter to filter different impurities in the crude oil and provide clean crude oil. A vacuum drying system is then used to evaporate excess moisture for easier storage. Finally, the clean crude oil is introduced into the crude oil tank for temporary storage.

Filter

Filter

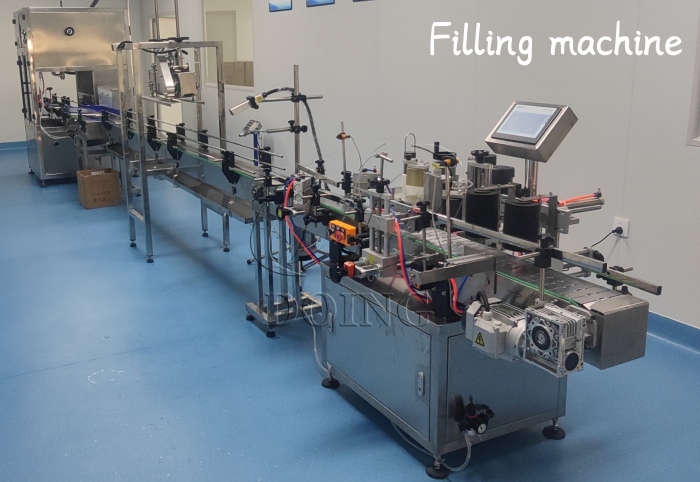

7. Filling machine: Edible oil filling machine is usually used in the final stage of large, medium and small edible oil production plants to fill bottles or bags with refined edible oil. According to the degree of automation of production, there are two types of edible oil filling machines: semi-automatic edible oil filling machine and automatic edible oil filling line.

Filling machine

Filling machine

The coconut oil processing machine produced by Glory Company can ensure the high quality and high output of coconut oil products. We can design and customize coconut oil processing machines with different configurations according to your situation and requirements. Drop us a message if you want to start a coconut oil processing business.

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line