What is rice bran oil made up of? What machines are used to produce rice bran oil?

FAQ / Chat on line / Give me a price / Date:April 7, 2020

As we know the rice bran oil is very nutritious, and popular among consumers, but many people don't know what rice bran oil is made up of. Is it made of rice bran? What is rice bran? How to produce rice bran oil by machines?

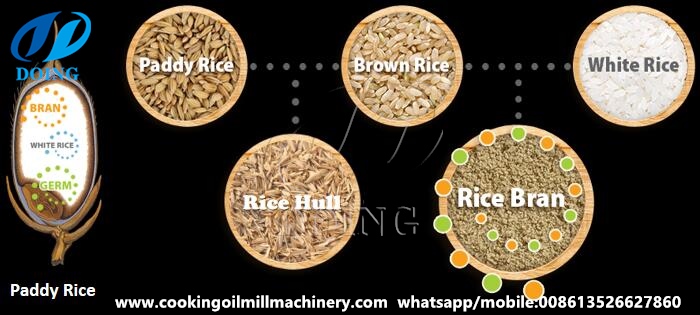

The structure of a paddy rice

The structure of a paddy rice

As its name shows that rice bran oil is surely made of rice bran. Rice bran is a small part of paddy rice, which is a kind of by-product in rice milling plant. In rice milling process, 100kg brown rice can get 5-8kg rice bran. So if you want to produce rice bran oil, to get the raw material from rice milling plant is the best method.

But I must remind you that the oil content of rice bran is about 10−23%, belongs to low oil content oil seeds. Generally, to produce rice bran oil by machines in factory is to use solvent extraction method and the input capacity of every day is 30 tons per day at least. So before starting the rice bran oil processing business, you need collect enough raw material -- rice bran. And then you can consider what machines you need to buy.

1. Rice bran pretreatment machines

Rice bran pretreatment machines are used to process the rice bran into best conditions for achieving better effect of solvent extraction. Rice bran pretreatment machines includes chaff rotary sifter, conditioner, puffing machine and plate dryer.

Four machines used in rice bran pretreatment process

Four machines used in rice bran pretreatment process

a. Chaff rotary sifter: to separate the rice bran and broken rice.

b. Conditioner: to adjust the moisture and temperature of rice bran.

c. Puffing machine: to change the inner structure of rice bran, make it softer and more easily to extract oil by solvent.

d. Plate dryer: to cool and dry the rice bran, make it store for long time, avoid becoming rancidity quickly.

2. Rice bran oil solvent extraction machines

Rice bran oil solvent extraction machines have four systems: Solvent extraction system, D.T.D.C system, Mixed oil evaporation and stripping system and Solvent cooling and recycling system.

Four systems of rice bran oil solvent extraction machines

Four systems of rice bran oil solvent extraction machines

The advantage of solvent extraction method is that it can make the residual oil rate less than 1%, and make the benefit maximum. Though the machine cost is higher than oil pressing plant, the production cost is much lower than that. So solvent extraction method is the most suitable method to produce rice bran oil. [Related reading: An overview of rice bran oil solvent extraction process technology]

3. Rice bran oil refining machines

Rice bran oil refining machines is used to refine the crude rice bran oil into refined product oil. It has three type: batch type, semi-continuous and full-continuous type.

Three types of rice bran oil refining machine

Three types of rice bran oil refining machine

The input capacity of each type we can design:

| Batch type: | 1tpd, 2tpd, 5tpd, 10tpd, 20tpd |

| Semi-continuous type: | 10tpd, 15tpd, 20tpd, 30tpd, 50tpd |

| Full-continuous type: | 30tpd, 50tpd, 100tpd, 200tpd, 300tpd, 500tpd, 600tpd |

The rice bran oil refining process generally consists of five processes: degumming, deacidification, decolorization, deodorization and dewaxing. The function of the rice bran oil refining process is to remove the different kinds of impurities and retain the nutritional ingredient and make the final product oil reach Grade 1 Level.

From rice bran pretreatment to crude rice bran refining process, it is a complete production line. If you want to produce crude rice bran oil and want to sell it to other oil refinery plant, you needn't buy the rice bran oil refining machines. Or if you already have a crude rice bran oil processing plant and want to further process the crude rice bran oil into refined oil, also welcome you contact Henan Doing Company. Our engineers can give you suitable suggestions based on your requirement.

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line