How is cottonseed oil made in cooking oil processing factory?

FAQ / Chat on line / Give me a price / Date:May 15, 2020

Cottonseed is a by-product of cotton manufacturing process, which can be used to make cooking oil. Its oil content is about 35%. In cooking oil processing factory, there are two kinds of technology which can be used to making cottonseed oil: pressing technology and solvent extraction technology. Here, Doing Company will introduce them for you one by one.

Cottonseed oil

Cottonseed oil

1. How is cottonseed oil made using pressing technology?

Firstly, the cottonseed need delinting treatment. The requirement of the cotton linter content is less than 3%. If your cottonseeds meet the requirement, this process can be skipped.

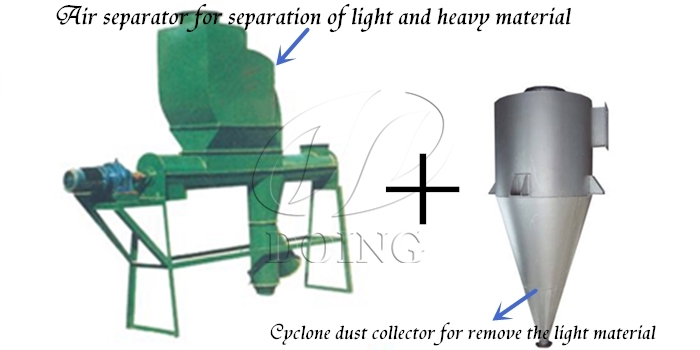

Secondly, the cottonseeds need to be cleaned by wind separator to remove the impurities.

The cleaning machines for cottonseed oil processing

The cleaning machines for cottonseed oil processing

Thirdly, clean cottonseeds will be cracked by crushing machine, whose purpose is to remove the cottonseeds shell. So after crushing, the cottonseed kernel and shell separating sieve and round play screen are used to separate the cottonseed and shell. Then, you can get clean cottonseed kernels.

Two kinds of cottonseed kernel and shell separating machine

Two kinds of cottonseed kernel and shell separating machine

Fourthly, the cottonseed kernels will be processed by flaking machine. The cottonseed kernels will become flakiness, which will make the oil yield rate increase.

The falking machine and cooking machine used in cottonseed oil pressing line

The falking machine and cooking machine used in cottonseed oil pressing line

Fifthly, flaky cottonseed kernels will be sent into cooking machine to adjust the temperature and moisture, and reach the best condition for pressing.

At last, cooked flaky cottonseed kernels will be put into oil press machine. The cottonseed oil will flow out continuously. This oil is crude cottonseed oil, which should be filtered by leaf filter firstly, and then be sent into edible oil refinery plant to be refined into product oil.

Cottonseed oil press machine

Cottonseed oil press machine

2. How is cottonseed oil made using solvent extraction technology?

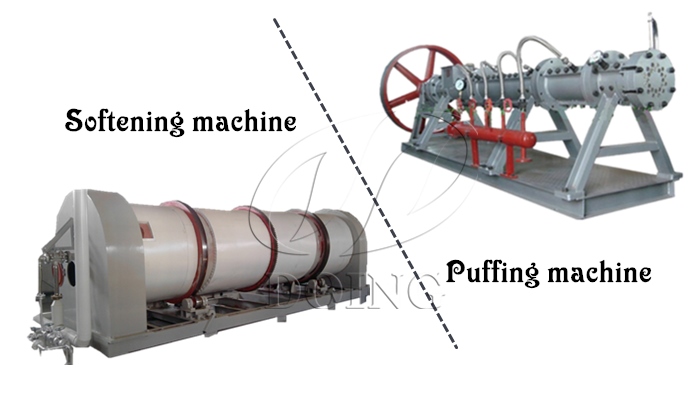

Using solvent extraction technology to make cottonseed oil also need pretreat the cottonseeds with some machines. The cleaning, shelling equipment is same as those used in pressing line. In order to improve the effect of solvent extraction, it also can add softening machine and puffing machine to process the cottonseed kernels.

Softening and puffing machine used to pretreat cottonseed kernel

Softening and puffing machine used to pretreat cottonseed kernel

As for the oil press machine, if using solvent extraction technology, it should be replaced by oil pre-pressing machine, whose residual oil rate is about 15%. Then the cottonseed cakes will be sent to cottonseed oil solvent extraction plant to extract oil out.

Cottonseed oil solvent extraction plant

Cottonseed oil solvent extraction plant

Cottonseed oil solvent extraction plant is to use n-hexan to extract the oil from cottonseed cakes, and the final residual oil rate can be less than 1%. The oil you get is also crude cottonseed oil, which must be sent into edible oil refinery plant to be refined into product oil.

The above is the introduction of crude cottonseed oil processing technology in cooking oil processing factory. If you also want to know the crude cottonseed oil refining technology, you can see another article--Cottonseed oil refining process introduction

If you want to make crude cottonseed oil by pressing or solvent extraction technology, or want to refine the crude cottonseed oil into product oil, you can contact us directly.

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line