Cottonseed oil refining process introduction

FAQ / Chat on line / Give me a price / Date:May 15, 2020

Cottonseed oil refining process mainly includes five steps: degumming, deacidification, decolorization, deodorization and fractionation. Each step has different effect in the whole cottonseed oil refining process. You can continue reading to learn about the details.

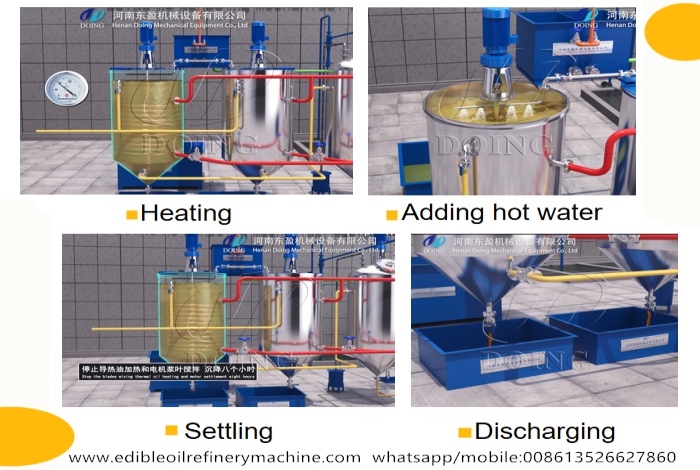

1.Degumming process of cottonseed oil

The purpose of cottonseed oil degumming is to remove the colloidal impurities in crude oil, because colloidal impurities will influence the stability of cottonseed oil and the effect of cottonseed oil refining and further processing. Then how to degum in cottonseed oil refining process?

Usually add a certain amount phosphoric acid solution, which can make the colloidal impurity absorb water for cohesion. Then the colloidal impurities will sink to be separated with oil.

Degumming process of cottonseed oil

Degumming process of cottonseed oil

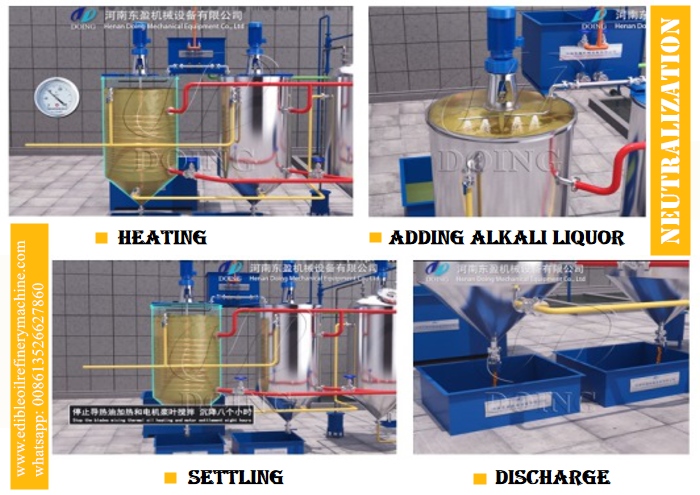

2.Deacidification process of cottonseed oil

Cottonseed oil deacidification is to remove the free fatty acid from crude cottonseed oil. Free fatty acid is also called FFA, which is the main factor to make the oil rancidity, so it should be removed. Cottonseed oil deacidification process has two kinds: chemical and physical. The chemical deacidification process is to add alkali liquor to react with FFA to generate nigre and the physical deacidification process is using high temperature steam to distill the FFA out.

Chemical deacidification process of cottonseed oil

Chemical deacidification process of cottonseed oil

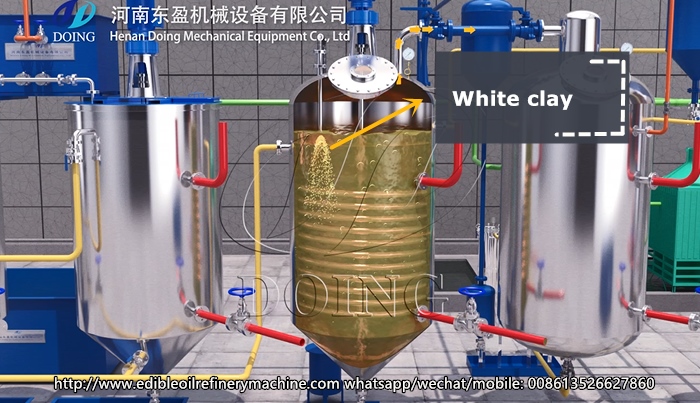

3.Decolorization process of cottonseed oil

Cottonseed oil decolorization process is mainly to make the oil color more lighter, and qualified the national standard. In cottonseed oil refining process, use white clay to absorb the pigments and then filter the waste clay out. The whole decolorization process is state of vacuum, and the amount of white clay required should be calculated by the engineer based on the parameters of crude cottonseed oil and requirement of final oil.

The decolorization process in batch type oil refinery plant

The decolorization process in batch type oil refinery plant

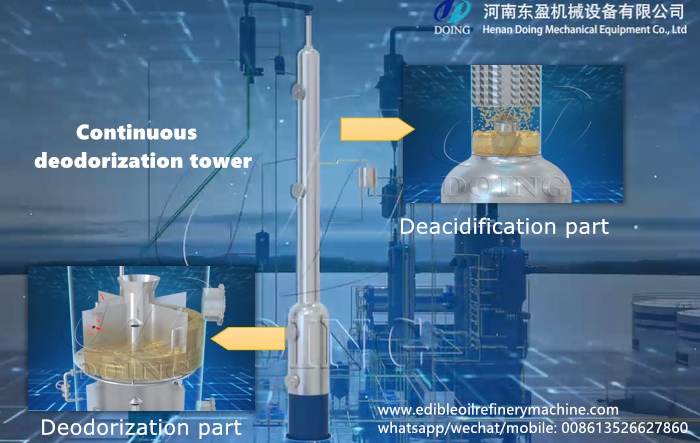

4.Deodorization process of cottonseed oil

Deodorization process of cottonseed oil often uses distillation principle. Inject high temperature steam, and the odors will be distilled out. The deodorization process can not only remove the odors from crude oil, but also improve smoke point, flavor, steadily and quality of final oil.

The structure of continuous deodorization tower

The structure of continuous deodorization tower

5. Fractionation process of cottonseed oil

Cottonseed oil fractionation process is similar with palm oil. Through cooling, crystallization and filtration, you can get two parts: cottonseed oil olein and cottonseed oil stearine.

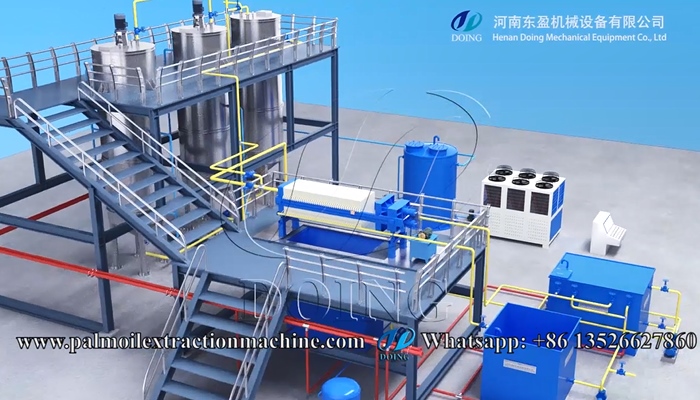

The cottonseed oil fractionation equipment 3d picture

The cottonseed oil fractionation equipment 3d picture

These are the introduction of cottonseed oil refining process. If you still have any questions or want to set up a cottonseed oil refinery plant, welcome you to send the message to us. Our sales manager will contact you as soon as possible.

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line