Which oils need to be dewaxed? What is the process of edible oil dewaxing?

FAQ / Chat on line / Give me a price / Date:September 4, 2024

Wax is a high molecular lipid with a high melting point and poor solubility in oil. It will affect the taste and transparency of edible oil and is not easily absorbed by the human body. Therefore, edible oil needs to be dewaxed. However, not all oils need to be dewaxed. Dewaxing is mainly aimed at those oils that are easy to precipitate wax at low temperatures, such as sunflower oil, rice bran oil, corn germ oil, tea seed oil, etc. These oils will become turbid at low temperatures when they are not treated, affecting transparency and taste. Peanut oil, palm oil, sesame oil, etc., don't need this step due to their own characteristics. Generally speaking, the process of edible oil dewaxing is divided into four steps: heating, cooling, crystallization, filtration.

1. Heating

First, the refined edible oil should be heated to 55˚C, which is to make sure that all the crystal in edible oil have been broken. At room temperature, a part of the solid wax in the oil has precipitated crystals. In order to achieve a good dewaxing effect, it is necessary to heat the oil with a steam heater before dewaxing, destroying the existing crystals. This will achieve a better crystallization effect, and this process can also be called crystal breaking.

2. Cooling

After crystal breaking, the oil needs to be cooled to a low temperature, usually below 0°C, but it depends on the type of oil and the melting point of the wax. The cooling process causes the wax to begin to crystallize.

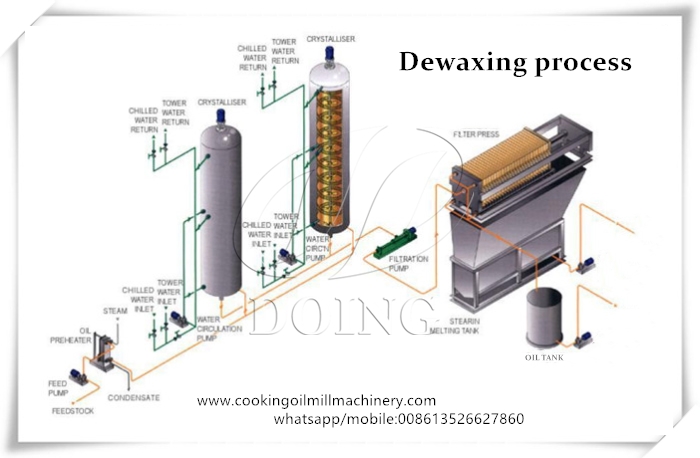

Dewaxing process 3d picture

Dewaxing process 3d picture

3. Crystallization

Under low temperature conditions, the wax will gradually form larger crystalline particles. In order to promote the formation of crystals, slow cooling and stirring can be used. The crystallization tank is equipped with a variable speed mechanical stirrer to ensure uniform stirring. When the oil appears in the liquid soft fat as semi-solid hard fat crystals, prepare to filter. If the crystallization effect is not good, send the slurry to the feed oil heater for re-crystallization.

4. Filtration

When the wax is fully crystallized, the crystallized wax is separated from the oil by filtration. We recommend the plate and frame filters. Plate filter is a kind of filtering equipment commonly used in edible oil production process. It includes filter frame, filter plate and filter cloth.

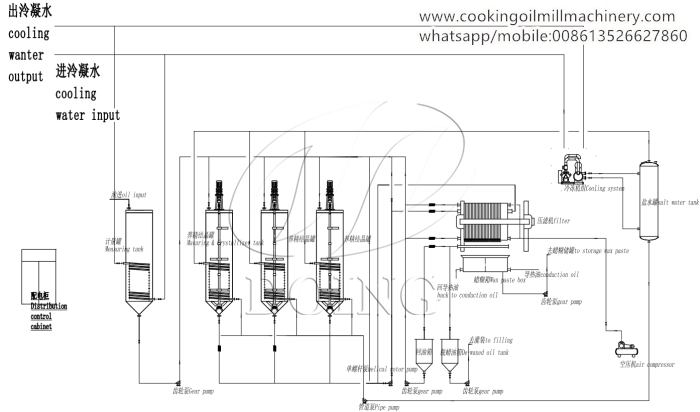

Dewaxing process flow chart

Dewaxing process flow chart

It should be noted that the temperature and time should be controlled during the process of edible oil dewaxing to avoid excessive crystallization of wax or other components in the oil. At the same time, for different types of oils, the dewaxing process parameters will also be different and need to be adjusted according to actual conditions.

The process of edible oil dewaxing is to improve the transparency and stability of oils, change the quality of oils, make them clearer, and reduce precipitation and deterioration during storage and transportation. The clarity and brightness of dewaxed edible oil meet the national standard. In general, our customers purchase both refining and dewaxing equipment to obtain high quality edible oil. Henan Doing Company is a professional edible oil equipment manufacturer. Any questions about edible oil refining, the process of edible oil dewaxing and fractionation, our engineers can give you professional suggestion. Welcome to contact us!

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line