Sunflower oil processing plant

Sunflower oil processing plant / Chat on line / Give me a price

Sunflower and sunflower seeds(with shell and without shell)

Sunflower and sunflower seeds(with shell and without shell)

Sunflower seeds is a common oilseeds, in which there are 45-54% oil content. Sunflower oil, with golden color, clear and transparent, fragrance oil, is a kind of popular edible oil among people.

Sunflower oil contains a lot of linoleic acid and other essential unsaturated fatty acids, can promote the regeneration and growth of human cells to protect skin health, and reduce the deposition of cholesterol in the blood. It is an advanced nutritional oil.

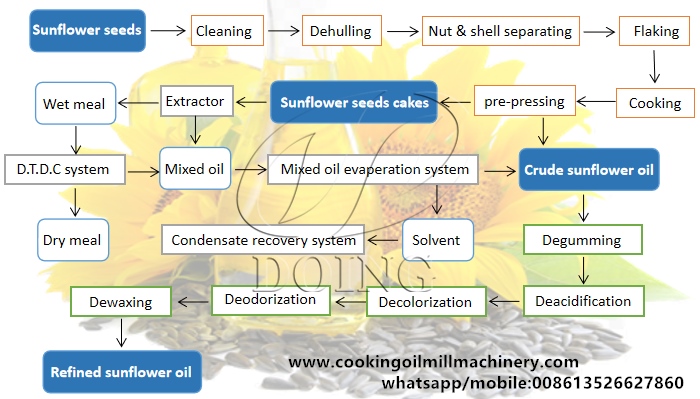

While how to make sunflower oil using sunflower oil mill machinery? Here I will introduce the main process of sunflower oil production process.

Sunflower oil production process flow chart

Sunflower oil production process flow chart

1. Sunflower seeds pretreatment & pre-pressing section

Sunflower seeds is a kind of high oil content oilseed, so the pre-pressing is necessary for making sunflower oil. Through a series of equipment processing, the sunflower seeds are adjusted in the best condition, and then sent into sunflower oil pre-pressing machine to extract part of sunflower oil.

The pretreatment machines are as following picture shows:

The sunflower seeds pretreatment machines and pre-pressing machine

The sunflower seeds pretreatment machines and pre-pressing machine

2. Sunflower oil solvent extraction section

Sunflower oil solvent extraction plant utilizes for extracting the maximum oil out from the sunflower seeds cakes. The final oil residue can be less than 1%. It is usually suitable for large capacity sunflower oil processing plant above 20tpd.

The processing flow chart of sunflower oil solvent extraction plant

The processing flow chart of sunflower oil solvent extraction plant

3. Sunflower oil refining section:

Sunflower oil refinery plant is to remove harmful impuries and useless substance, such as protein, phospholipid, pigment, moisture, wax and other impurities. And then the refined sunflower oil can reach the standard of food and storage.

Three types of sunflower oil refinery plant

Three types of sunflower oil refinery plant

(1) Degumming & Deacidification section: Use P-acid to remove gums, alkali to react with acid and then water to rinse.

(2) Decoloring/bleaching section: To remove pigments, get bleaching oils and dehydrated oil.

(3) Deodorizing section: To remove the odor components in oil.

(4) Dewaxing section: To remove the wax in the sunflower oil, in order to get the higher quality cooking oil.

Henan Doing Company is a professional manufacturer of cooking oil mill machinery. We have been in cooking oil machine manufacturing industry for 40 years. For sunflower oil processing, our engineers has some advice according to the sunflower seeds amount you want to process per day.

| 1-10tpd | Screw sunflower oil press machine |

| 10-20tpd | It is better to start sunflower oil mechanical press processing line. |

| Above 20tpd | You can choose mechanical press processing line or solvent extraction processing line. |

We are looking forward to cooperating with you! Welcome to contact us. Our engineers will service you.

Related product recommend

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line