Home>Product>Whole production line>Peanut oil processing plant>5 tons per day groundnut oil processing machine

Home>Product>Whole production line>Peanut oil processing plant>5 tons per day groundnut oil processing machine

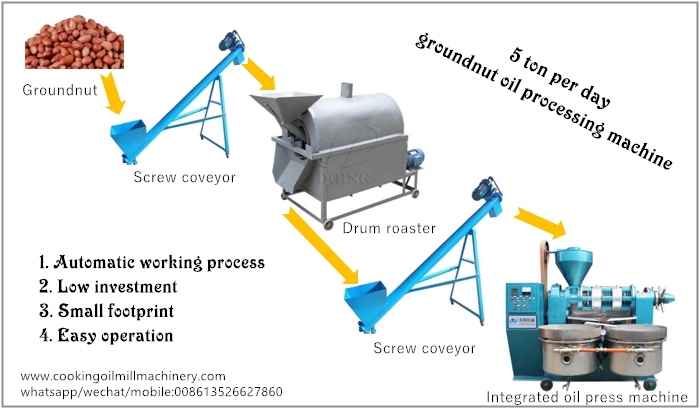

5 tons per day groundnut oil processing machine

Peanut oil processing plant / Chat on line / Give me a price / Date:May 21, 2020

The introduction of 5 tons per day groundnut oil processing machine:

5 tons per day groundnut oil processing machine can process 5 tons groundnuts within 12 hours and make sure the residual oil rate is 6-8%. The 5 tons per day groundnut oil processing machine provided by DOING Company is a small scale groundnut oil pressing line, which includes not only the oil press machine with vacuum filter, but also conveyors, roaster and PLC control system.

The working process of 5 tons per day groundnut oil processing machine:

The working process of 5 tons per day groundnut oil processing machine

The working process of 5 tons per day groundnut oil processing machine

As the above picture shows, firstly, through screw conveyor, the groundnuts are transported to the drum roaster for adjust the temperature and moisture of groundnuts to improve the oil yiled rate.

Then, the groundnuts will be transported to the integrated groundnut oil press machine with vacuum filter for squeezing out the groundnut oil.

Finally, the crude groundnut oil will be filtered by the vacuum filter directly. The filtered groundnut oil can be eaten directly when cooking food. And the pressed groundnut oil is always very popular among consumers.

The specific parameters of 5 tons per day groundnut oil processing machine:

| Machine name | Machine model | Quantity | Power(KW) |

| Screw conveyor | TSLS100 | 2 | 1.1 |

| Drum roaster with stove fire | YHCZ500 | 1 | 3.7 |

| Integrated oil press machine with vacuum filter | YZYX160 | 1 | 28.2 |

| PLC control system | - | 1 | - |

Supplementary instruction:

1. The drum roaster can be customized based on the customers' needs. It has three kinds: with stove fire, electric heating and gas type.

2. The set of 5 tons per day groundnut oil processing machine only need one worker to operate very easily.

3. The plant area of the 5 tons per day groundnut oil processing machine need reach 30㎡.

4. The maximum input can reach 6 tons groundnuts per day.

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line