What should be avoided during peanut oil production?

FAQ / Chat on line / Give me a price / Date:March 26, 2024

If you want to build a peanut oil processing plant, Doing Holdings - Henan Glory will provide you with some useful suggestions in peanut oil production which can make you avoid detours.

1. About the peanut raw material

In the process of peanut oil production, you should choose dry peanuts. Because the selection of peanut raw materials is very important, it is related to the quality of the final peanut oil. When peanuts are harvested, they must be dried as soon as possible, because moist peanuts should not be stored and are prone to mold, which will affect the quality of the final peanut oil and affect your health after consumption.

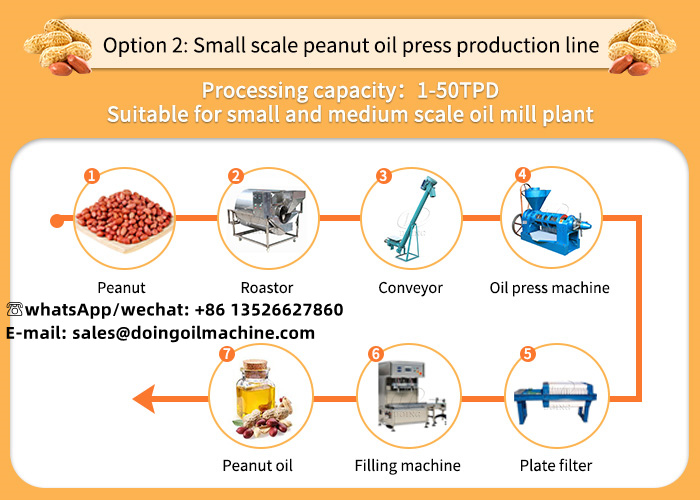

Peanut oil production machines

Peanut oil production machines

2. Choose reliable peanut oil processing machines

2.1 Don't choose low quality machines

Peanut oil processing machine is the core of the production and processing process of peanuts, so do not choose low quality peanut production machines. Choosing high-quality peanut processing machines can not only ensure long-term operation, but also ensure the oil yield. Inferior peanut oil processing machines have insufficient cleaning and crushing of peanuts raw materials, have more impurities or have too large peanut particles, which will affect the quality and extraction rate of peanut oil.

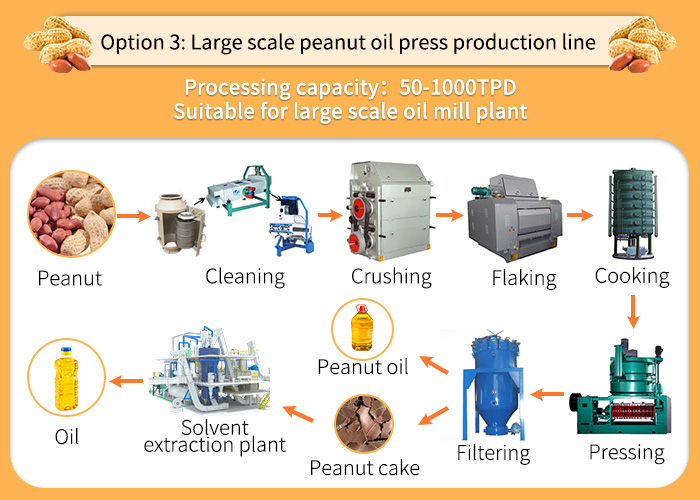

Peanut oil production machines

Peanut oil production machines

2.2 Do not choose non-customized peanut oil processing machines

For different processing volumes and different processing requirements, different peanut oil production machines need to be designed. Customized peanut oil production machines can help you achieve higher profits only if the project is designed according to your needs.

2.3 Do not choose peanut oil production machines without after-sales service

The installation and debugging of peanut oil production machines will affect the quality and output of peanut oil. Only the peanut oil production machine after various debugging by engineers can extend the service life and enhance the processing capacity of the peanut oil production machine. Therefore, choosing a peanut oil production machine manufacturer with after-sales service can greatly reduce the trouble in the subsequent production of peanut oil.

Peanut oil production machines

Peanut oil production machines

Doing Holdings - Henan Glory company is a modern enterprise engaged in peanut oil production machine manufacturing for many years. Doing Holdings - Henan Glory has our own factory and engineer team, which can design corresponding projects according to the different needs of different customers, and debug the parameters of peanut oil production machines to improve the economic benefits of customers. If you encounter any problems when purchasing Doing Holdings - Henan Glory’s peanut oil production machine, our engineers will actively solve these problems for you and give you a better user experience.

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line