What is the rice bran oil production process?

FAQ / Chat on line / Give me a price / Date:August 23, 2024

As one of the healthiest cooking oils, rice bran oil has also begun to be recognized in recent years. However, you may not know the rice bran oil production process, and rice bran oil production machines needed. If you are interested in rice bran oil production process or are ready to set up a rice bran oil processing plant, DOING Company can provide not only a complete set of rice bran oil production machines but also help you to design your factory depending on your requests and your budget, the following rice bran oil production process may help you.

Rice bran pretreatment

Before rice bran enter the rice bran oil solvent extraction machine for rice bran oil production, they need to go through processes such as cleaning, moisture conditioning, puffing and drying, which is called rice bran pretreatment process. Adequate pretreatment of rice bran can improve the quality and yield of rice bran oil. The rice bran obtained during rice processing will contain a small amount of impurities, so the rice bran and broken rice should be separated by the chaff rotary sifter to get pure rice bran. After that, the rice bran enters the conditioner to adjust the temperature and moisture, and then the puffing machine make it into a porous and soft structure, which is conducive to the extraction. Finally, the puffed rice bran goes into a plate dryer for drying and cooling.

Rice bran oil pretreatment machines

Rice bran oil pretreatment machines

Rice bran oil solvent extraction

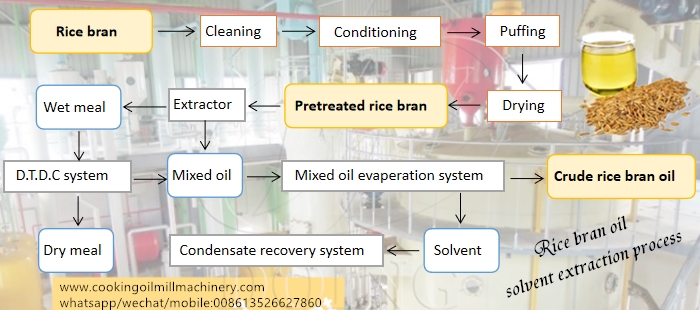

The second rice bran oil production process is rice bran oil solvent extraction, which uses n-hexane as the solvent to extract rice bran oil from puffed rice bran. The extraction process technology mainly include four process: rice bran oil solvent extraction, wet meal DTDC system, mixed oil steaming and stripping and solvent recovery.

Rice bran oil solvent extraction process

Rice bran oil solvent extraction process

The first step is after the rice bran was pretreated, the puffed rice bran particles were injected into the extractor, sprayed with the solvent n-hexane, and the oil in the rice bran was dissolved in the solvent to form the mixed oil. Then, the mixed oil is filtered through the sieve, and the cleaner mixed oil obtained will enter the mixed oil evaporation system. The second step is the wet meal treatment, the meal including a mount of the solvent about 25%-35%. And this part of solvent can be recovered and resumed so we use the desolventizer toaster to separated the solvent from meal. The third step is evaporation and stripping of solvents. We use the evaporator, stripper and other equipment to completely evaporate the solvent from the oil to obtain clean oil. The last part is solvent recovery, which mainly uses the condenser to convert the gaseous solvent into aliquid state, and uses the water distribution tank to recover the solvent for recycling.

Rice bran oil refining

After being extracted, the crude rice bran oil should be refined. The rice bran oil refining process contains degumming, deacidification, decolorization and deodorization, which is used to remove gums, FFA, pigments and bad odors, aiming at improving the rice bran oil storage stability, flavor and color. Henan Doing Company's rice bran oil refining machine has three kinds of intermittent, semi-continuous and fully continuous, which can be selected according to the output.

Three types of rice bran oil refining machines

Three types of rice bran oil refining machines

Above is the rice bran oil production process, we have rich experience in designing the process and manufacturing the rice bran oil production machines. If you need, contact us!

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line