What equipment is needed to manufacture soybean oil by solvent extraction method?

FAQ / Chat on line / Give me a price / Date:December 1, 2023

The solvent extraction method is the best choice for large scale soybean oil extraction plant, because of its low residual oil rate and with higher quality of meal. But its investment is also higher than the pressing method. To manufacture soybean oil by solvent extraction method needs two sets of equipment, including soybean pretreatment equipment and soybean oil solvent extraction equipment. Then, I will introduce them to you one by one.

1. Soybean pretreatment equipment

The oil content rate of soybeans is around 17%, belonging to low oil content oil seeds. Generally, engineers recommend adopting first puffing then directly solvent extraction method. So the soybean pretreatment equipment contains cleaning equipment, crushing equipment, softening equipment, flaking equipment, cooking equipment and puffing equipment.

The soybean oil pretreatment equipment

The soybean oil pretreatment equipment

As the above picture shows, the cleaning equipment has vibrating screen, magnetic separator and de-stonner, which are used to remove the impurities from soybean, and improve the quality of crude soybean oil. Other equipment is used to condition the size, density, temperature and humidity of soybeans, and make it more easily to be extracted oil out.

2. Soybean oil solvent extraction equipment

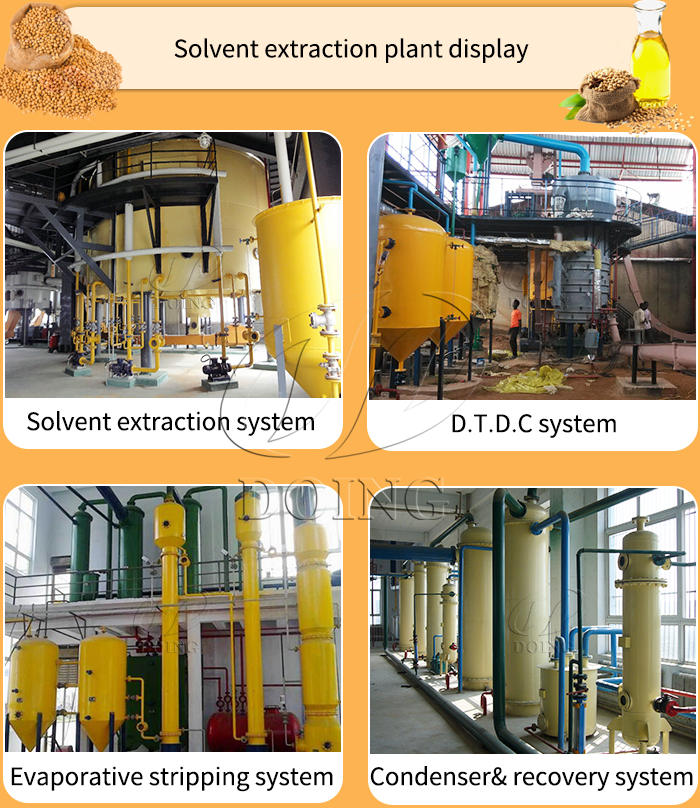

The equipment in the soybean oil solvent extraction workshop contains the following four main parts:

1) Soybean oil solvent extraction system:

using N-hexane to react with puffing soybean materials, then you can get two parts: the mixture of solvents and oil called miscella oil and the mixture of solvents and meal called wet meal.

2) D.T.D.C system:

D.T.D.C means desolventizer, toaster, dryer and cooler, which is mainly used to separate the solvents from the wet meal, then the dried meal will be sent to meal silo for storage.

The soybean oil solvent extraction equipment

The soybean oil solvent extraction equipment

3) Miscella oil evaporation system:

since miscella oil contains solvents, we need to separate the solvents from the crude soybean oil by first evaporation, second evaporation and stripping tower, then we can condensate the oil and pump it into a crude oil tank, and you can choose to sell the crude oil to the refinery factory or you can set up a soybean oil refinery plant by yourself.

4) Solvents condensing and recovery system:

Usually producing one ton crude soybean oil through the soybean oil solvent extraction method needs around 4kg solvents. Considering of cost-effectives and environmental protection, we add this system to recycle the solvents by condensing it and collecting it for reuse.

The above is the equipment introduction used to manufacture soybean oil by solvent extraction method. If you want to buy soybean oil solvent extraction equipment, welcome to contact us! Our engineers team will give you professional suggestions on choosing equipment.

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line