What equipment is needed for a 5tpd soybean oil refining production line?

FAQ / Chat on line / Give me a price / Date:September 19, 2024

The 5tpd soybean oil refining production line belongs to intermittent refining in terms of refining type, and usually uses chemical refining technology. The processes involved include degumming, deacidification, decolorization and deodorization. Through four processes, various impurities in soybean crude oil are removed to meet the standards of refined oil. Henan Glory Company will introduce the soybean oil refining equipment and work sections to help investors better understand.

Degumming section

Refining tank: By adding hot water, the colloid phospholipids in the soybean oil absorbs water, expands and condenses, which is convenient for subsequent separation.

Hot water mixing box: There is a mixing box of alkali solution and hot water. Hot water is used to remove colloid-soluble impurities in oil.

Separation equipment: Centrifuges or sedimentation tanks are used to separate hydrated colloid precipitates and improve the clarity of oil products.

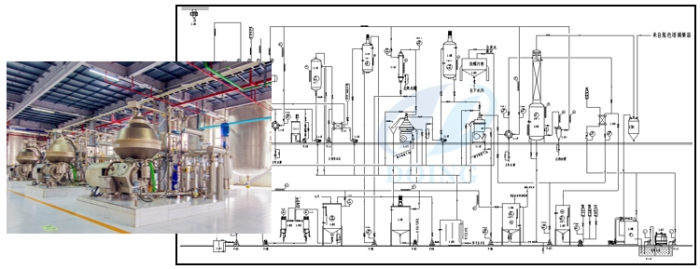

Soybean oil degumming and deacidification equipment

Soybean oil degumming and deacidification equipment

Deacidification section

Alkali refining tank: Under heating, add an appropriate amount of NaOH to neutralize the free fatty acids in the oil and reduce the acid value.

Neutralization reactor: Ensure that the acid-base reaction is fully carried out.

Separation equipment: Sedimentation tank can separate the neutralized soap stock from the oil.

Decolorization section

Decolorization tank: Decolorizationtank is usually the tool used in soybean oil refining process to remove impurities such as pigments, metals, and residual soap from the soybean oil. Inhale definite amount of decoloring agent (white clay) into the refined soybean oil, continuously stirring and heating for a period of time.

Filter: After that, pump the mixture of oil and white clay into filter to separate oil and waste white clay,ensuring the quality of the oil.

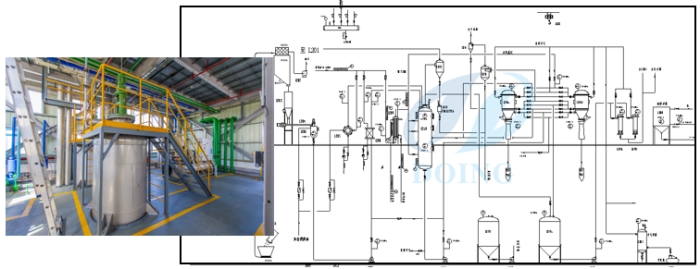

Soybean oil decolorization equipment

Soybean oil decolorization equipment

Deodorization section

The soybean oil deodorization section uses steam distillation to remove odorous substances in oil under high temperature and high vacuum conditions. The general operating temperature can reach 200℃.

Deodorization tower: Steam is introduced under appropriate air pressure, and the difference in volatility between odorous substances and triglycerides in oil is used to remove odorous substances under high temperature and high vacuum conditions by means of steam distillation.

Vacuum pump: It provides a vacuum environment for the deodorization and decolorization sections to ensure that the deodorization process is carried out in a low-oxygen environment, improving the deodorization efficiency and oil stability.

Cooling system: The deodorized oil needs to be cooled quickly to prevent oxidation and maintain the quality of the oil.

Overall, soybean oil refining equipment plays a crucial role in the soybean oil refining production line, ensuring that the final product meets quality standards and is suitable for various applications in the food industry. As a supplier of soybean oil production line in the industry, Henan Glory Company can provide solutions from equipment selection, production line design to installation and commissioning, helping companies to produce soybean oil efficiently and safely.

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line