How to extract oil from rice bran? What equipment is needed?

FAQ / Chat on line / Give me a price / Date:June 15, 2023

Rice bran oil is the raw material of rice bran, a by-product of rice processing. It is usually extracted by pressing or chemical solvent extraction. Next, we'll discuss both methods and what machines will be used.

pretreatment equipment

pretreatment equipment

1. Pretreatment pressing method: In this process, we will use the bran and threshing sieve, tempering pot, puffing machine, flat drying equipment. The rice bran obtained in the rice processing process will contain a small amount of impurities, so the rice bran and broken rice should be separated by the chaff separation screen to obtain pure rice bran. Then, the rice bran goes into the tempering pot, and a small amount of steam is steamed and stir-fried. Then, enter the puffing equipment, and use the pressure difference to make it into a porous and soft structure, which is conducive to the extraction of oil. Finally, the puffed rice bran enters the plate drying equipment for drying and cooling. The pretreated rice bran can be sent directly to the oil presser, or it can be stored first (about 1 week). Generally speaking, to extract oil from rice bran, we suggest using solvent extraction method, because the oil content of rice bran is very low, and the oil yield of pressing method is lower than solvent extraction method. When the daily processing capacity is above 30 tons, using solvent extraction method can get more oil.

solvent extraction equipment

solvent extraction equipment

2. Solvent extraction method: The equipment of using solvent extraction method contains the former pretreatment equipment and solvent extractor, D.T.D.C system, mixed oil evaporation system and solvent recovery system. The first step is after the rice bran was pretreated, the puffed rice bran particles were injected into the extractor, sprayed with the solvent n-hexane, and the oil in the rice bran was dissolved in the solvent to form the mixed oil. Then, the mixed oil is filtered through the screen, and the cleaner mixed oil obtained will enter the mixed oil evaporation system. The second step is the wet meal treatment, the meal including a mount of the solvent about 25%-35%. And this part of solvent can be recovered and resumed so we use the DTDC desolventizer toaster with integrated to separated the solvent from meal. The third step is evaporation and stripping of solvents. We use the first evaporator, second evaporator, stripper and other equipment to completely evaporate the solvent from the oil to obtain clean oil. The last part is solvent recovery, which mainly uses the condenser to convert the gaseous solvent into aliquid state, and uses the water distribution tank to recover the solvent for recycling.

edible oil refining equipment

edible oil refining equipment

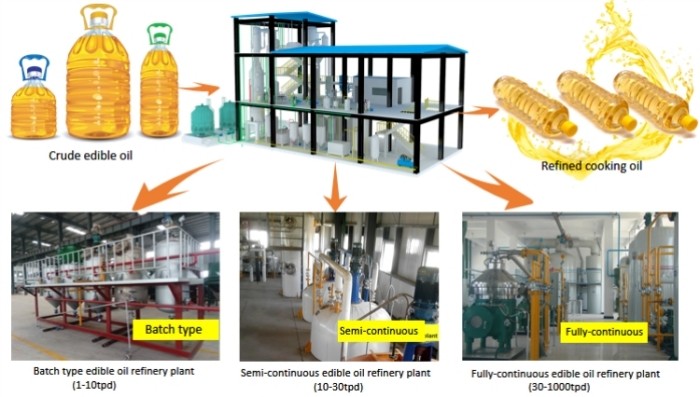

If using solvent extraction method to extract oil from rice bran, the crude rice bran oil should be refined by rice bran oil refining equipment, because it will has a little solvent which should be removed. Our rice bran oil refining equipment has three types: batch type, semi-continuous type and full-continuous type, which can be chose based on the capacity. The above is the introduction of how to extract rice bran oil and its equipment. If you want to extract rice bran oil and want to buy equipment, you can contact us. Henan Glory Oil & Fats Engineering CO.,LTDhas more than 10 years of experience in rice bran oil extraction and has our own equipment factory production line. We have a professional team of engineers who can provide you with some advice andequipment for rice bran oil production.

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line