What equipment is needed to start a soybean oil processing plant?

FAQ / Chat on line / Give me a price / Date:September 27, 2023

Soybean oil is bright in color and rich in nutritional value. In recent years, it has been favored by more and more consumers. The market demand has been increasing year by year, so a large number of soybean oil processing plants have emerged. Many investors are confused when watching this project. What equipment is needed to start a soybean oil processing plant? In fact, large-scale soybean oil processing plants include pretreatment equipment, pressing or solvent extraction equipment, and refining equipment. Below, Henan Glory Company will introduce the specific information and functions of these equipment in detail.

Pretreatment equipment

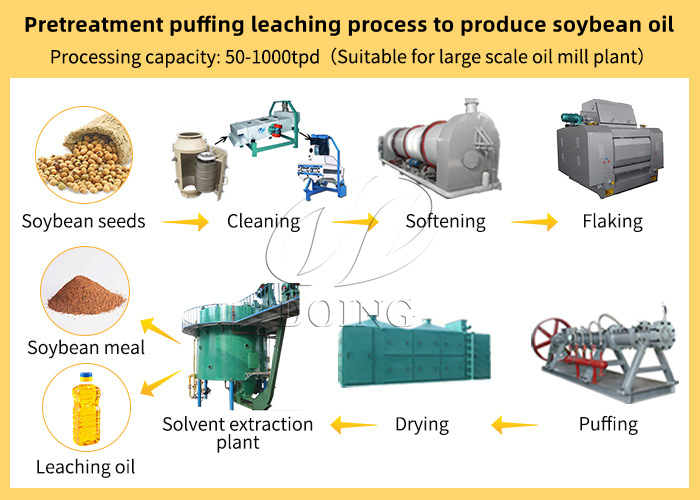

Soybeans need to go through processes such as drying, cleaning, softening, flaking, cooking before pressing oil, so that the soybeans are in the most suitable state for the oil to flow out. This process is called pretreatment. Sufficient pretreatment of raw materials can improve oil quality and oil yield, therefore, pretreatment equipment is the first equipment that needs to be considered when opening a soybean oil processing plant. Pretreatment equipment includes an air thermal dryer for drying soybeans, a vibrating screen, a magnetic separator and a destoner for removing dirt, leaves, nails and other impurities. And a softening pot is used to prevent soybeans from damaging the machine. Finally, a cooker is used to adjust the temperature and moisture of the soybeans. After cooking, the temperature of the soybeans is generally around 100 degrees and the moisture content is less than 5%.

Soybean oil pretreatment equipment

Soybean oil pretreatment equipment

Pressing or solvent extraction equipment

Soybean oil processing technology includes pretreatment pressing method and pre-pressing solvent extraction method. The equipment used in the soybean oil processing plant at this stage varies according to the customer's processing technology.

Pretreatment and pressing method: The pretreatment and pressing method requires pretreatment equipment and pressing equipment. The pretreated soybean raw materials can be directly entered into the oil press for pressing, and then a plate filter is used to filter the pressed crude oil.

Pre-pressing and solvent extraction method: The pre-pressed soybean oil cake after pre-treatment also contains a certain amount of oil. The oil in the oil cake is extracted into the solvent through the principle of chemical solvent extraction. The main equipment used in this section includes extractors, steam strippers, evaporators, oil-water separators, condensers, stripping towers, etc.

Soybean oil pre-pressing and solvent extraction equipment

Soybean oil pre-pressing and solvent extraction equipment

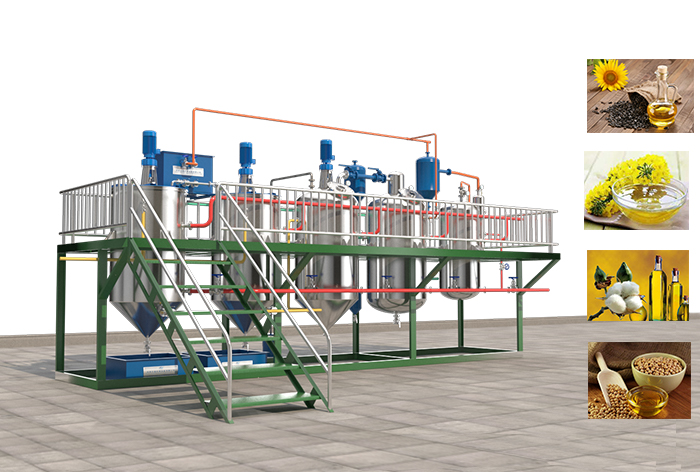

Refining equipment

Regardless of pressing or solvent extraction, the final product is crude oil. To obtain edible oil that meets national standards, refining equipment is essential for setting up a soybean oil processing plant. The refining equipment used in this process includes refining pots, decolorization pots, deodorization pots, filters, vacuum pumps, thermal oil furnaces, fatty acid traps, shielding pumps, fatty acid circulation tanks, steam boiler systems, etc. Henan Glory Company provides intermittent, semi-continuous and fully continuous soybean oil refining equipment, and can match the appropriate soybean oil refining equipment according to the processing capacity of the customer's soybean oil processing plant.

Soybean oil refining equipment

Soybean oil refining equipment

The above is the equipment needed to open a soybean oil processing plant, but the equipment is not static. Henan Glory Company can increase or decrease the equipment according to the processing capacity and detailed requirements of different customers' soybean oil processing plants, while ensuring the oil output. efficiency while ensuring greater benefits with less investment cost. If you want to know which equipment corresponds to different processing capacities, please feel free to consult Henan Glory Company.

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line