Home>Blog>What are the requirements for the structure and properties of the embryo during oil production by solvent extraction?

Home>Blog>What are the requirements for the structure and properties of the embryo during oil production by solvent extraction?

What are the requirements for the structure and properties of the embryo during oil production by solvent extraction?

FAQ / Chat on line / Give me a price / Date:November 13, 2024

There are strict requirements on the structure and properties of the embryo when extracting oil. Porosity, particle size and shape, appropriate moisture content of embryo material, oil content and distribution etc are all key factors to ensure efficient solvent extraction and high quality oil. Through careful embryo treatment and optimization of conditions, the solvent extraction efficiency can be significantly improved and high-quality oil products can be obtained. Next, Henan Glory will give you a detailed introduction to the requirements for the structure and properties of the embryo during oil production by solvent extraction.

1. Porosity

The embryo should possess an appropriate level of porosity. High porosity allows the solvent to penetrate more easily into the interior of the embryo. This enables efficient contact between the solvent and the oil - containing components. So the pores should be of a suitable size and distribution to ensure that the solvent can reach the oil - rich regions without being hindered.

2.Particle Size and Shape

Particle Size: The particle size of the embryo is crucial. Smaller particles generally offer a larger surface - area - to - volume ratio. This means that more surface area is available for the solvent to interact with the oil. The effect of the solvent extraction will better, we can get enough oil.

Shape: The shape of the embryo also affects the extraction process. Spherical or near - spherical shapes can lead to better packing and flow characteristics. Irregular - shaped embryos may have more void spaces between them, which can influence the solvent flow and overall extraction efficiency.

3. Appropriate moisture content of embryo material

Generally speaking, if the moisture content is high, it is not easy for the solvent to penetrate into the cells to dissolve the oils and fats. Therefore, appropriate low moisture content is very important. The ideal moisture content of embryo material should be controlled between 7% and 12%. Different materials will have different moisture contents. Too high or too low moisture content will affect the penetration ability of the solvent and the dissolution rate of oils and fats.

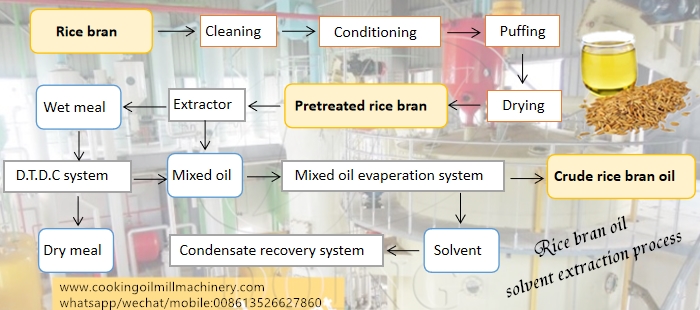

Rice bran oil solvent extraction process

Rice bran oil solvent extraction process

4. Oil Content and Distribution

The embryo should have a sufficient oil content to make the extraction process economically viable. The oil content varies depending on the type of raw material. For example, some oil seeds like soybeans may have an oil content of around 18 - 22%, while sunflower seeds can have an oil content of up to 40 - 50%. Moreover, the distribution of oil within the embryo is important. Uniform distribution ensures that the solvent can extract the oil evenly. If the oil is concentrated in certain regions, it may lead to incomplete extraction or require more complex extraction procedures.

5. Chemical Composition and Stability

Chemical Composition: The chemical composition of the embryo, apart from the oil, can affect the extraction process. It may contain proteins, carbohydrates, and other substances. These components can interact with the solvent in different ways. For example, some proteins may form complexes with the oil or the solvent, which can either enhance or impede the extraction process. Understanding the chemical composition helps in choosing the right solvent and extraction conditions.

Stability: The embryo should have a certain level of stability during the extraction process. It should not decompose or undergo unwanted chemical reactions with the solvent. For example, if the embryo contains heat - sensitive components, the extraction temperature and time need to be carefully controlled to prevent degradation and maintain the quality of the extracted oil. Our engineers will solve these for you.

Direct solvent extraction machines

Direct solvent extraction machines

Solvent extraction is generally suitable for oils with a processing capacity of 20 tons or more per day and a low oil content. Because the oil production by solvent extraction method relies on the mutual solubility of organic solvent and oil to extract oil from embryo, the structure and properties of embryo have a significant effect on solvent extraction. In order to ensure the efficiency of the solvent extraction process and the quality of the oil, certain requirements must be put forward for the structure and properties of the material embryo. Henan Glory company's solvent extraction equipment has been optimized for many years, and has rich experience in project landing, which can ensure that the structure and performance of the embryo meet the oil production conditions and maximize the benefit. If you are ready to start oil production by solvent extraction, or are interested in cooking oil processing equipment, please contact us.

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line