What are the process of and what machinery is used for crude palm oil extraction?

FAQ / Chat on line / Give me a price / Date:January 12, 2023

The steps involved in crude palm oil extraction include raw material reception, sterilization, threshing, digtesing, pressing, filtration process and vacuum dryer system and storage. Here are the specific process of and machinery used for crude palm oil extraction.

Palm oil extraction machine

Palm oil extraction machine

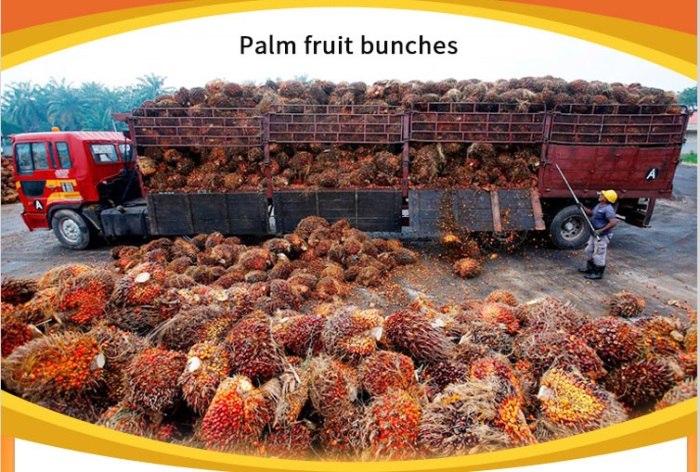

1. Palm fruit reception: the first is raw material reception in crude palm oil extraction. Fresh palm bunches collected from plantations need to be treated within 48 hours to prevent FFA from increasing and affecting the quality of the oil later on. They are transported by truck or other means to the factory, weighed and put into the unloading table for other processes.

Palm fruit reception

Palm fruit reception

2. Sterilizer: the purpose of sterilization section in crude palm oil extraction is to soften and sterilize the fruit so that it is easy to fall off and press.

Palm fruit sterilizer

Palm fruit sterilizer

3. Palm fruit thresher: thresher is mainly for separating palm fruit from palm fruit bunches in the process of palm oil processing. According to processing capacity per hour, Henan Glory Company have simple type thresher with capacity 500kg/h and drum type from capacity 1-2t/h to 15t/h. After threshing, palm fruit and empty palm fruit bunches will be separated effectively.

Plam fruit thresher

Plam fruit thresher

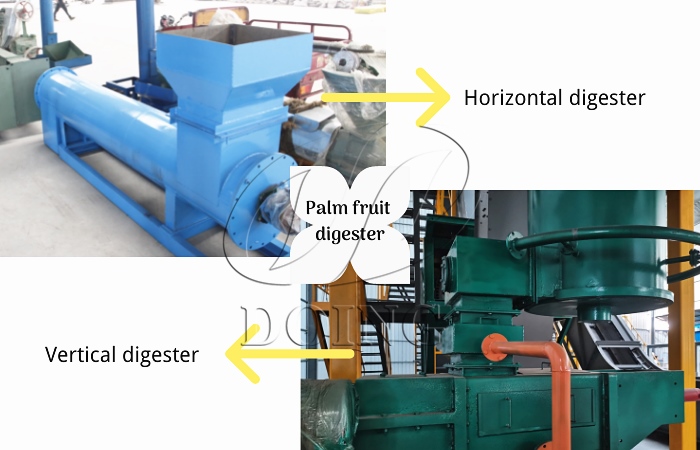

4. Digester: digester is for crushing palm pulp and breaking the cell of pulp in palm oil processing. The destruction of the fiber structure facilitates subsequent pressing and helps to improve the final oil yield. There are horizontal and vertical digesting tanks which can be chosen based on their factory design and area or other actual needs.

Palm fruit digester

Palm fruit digester

5. Presser: the pressing section in crude palm oil extraction is an important step. The oil press is used to press the palm fruit. The fruit and nut are separated from the front part of the oil press and extruded to get crude palm oil and palm nut. The oil press produced by Henan Glory Company has high oil yield and can maintain continuous production.

Screw palm oil press machine

Screw palm oil press machine

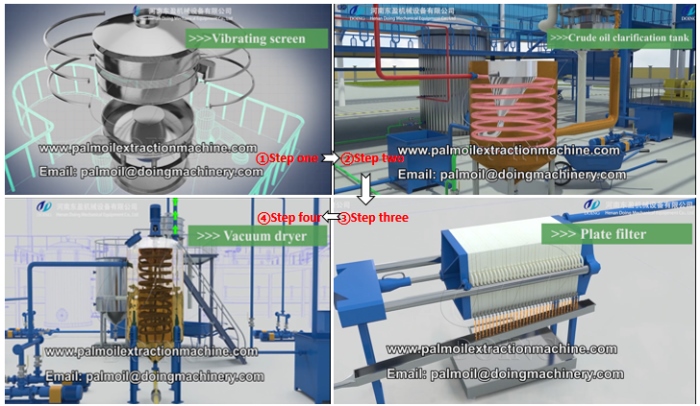

6. Oil clarification station: for the filtration stage in crude palm oil extraction, CPO is subjected to a series of filtration processes such as vibrating screen, oil clarification tank and plate filter, layer by layer filtration to ensure the quality of oil. If the water in the oil is not removed, it is difficult to keep it for a long time, so a vacuum drying system is needed. Then use a vacuum drying system to evaporate excess water for easier storage. Finally, the clean crude oil is introduced into the crude oil tank for temporary storage.

Palm oil clarification section

Palm oil clarification section

7. Oil storage tank: the final step is the storage and crude palm oil transportation in crude palm oil extraction. The crude oil is transported by truck or other means and stored.

Oil storage tank

Oil storage tank

These are the process of and machinery used for crude palm oil extraction, and we have been engaged in this industry for more than ten years. The machines required for these steps can be found in our company. If you are interested, please contact me.

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line