Troubleshooting common peanut oil expeller problems

FAQ / Chat on line / Give me a price / Date:July 25, 2025

Extracting peanut oil using a mechanical press (expeller) is the basis of many farm operations and small oil mills. While these peanut oil expellers are rugged and durable, they can arise from a number of issues that affect extraction efficiency, oil quality and machine longevity. Here is a quick guide to troubleshooting common peanut oil expeller problems:

1. Low Oil Yield

Symptoms: Oil yield is lower than expected.

Causes & Solutions:

(1) Incorrect Temperature Control: Before pressing, peanuts require specific conditioning and precise temperature monitoring. Make sure the peanuts are clean and lightly roasted to maximize oil extraction.

(2) Inadequate Pressure Settings: Under-pressurized systems leave oil trapped; excessive pressure causes rapid wear without proportional gain. Adjust screw speed and pressure according to the manufacturer's instructions.

(3) Clogged Screens: Clean or replace clogged filters to ensure oil flows smoothly.

2. Poor Quality Oil

Symptoms: Unusual taste, odor, or impurities in the oil.

Causes & Solutions:

(1) Internal Overheating: Monitor and keep the peanut oil expeller temperature within the recommended range to prevent oxidation.

(2) Quality of Peanuts: Use fresh, dry and high-quality peanuts; discard moldy or rotten ones.

(3) Inadequate Filtration: Invest in high-quality peanut oil pressing and filtration systems and clean them regularly to remove residues.

High-quality peanuts

High-quality peanuts

3. Excessive Power Consumption

Symptoms: Higher-than-usual power draw.

Causes & Solutions:

(1) Overloading: Feed peanuts gradually and avoid overloading the peanut oil expeller.

(2) Friction: Lubricate moving parts regularly to reduce friction.

(3) Compression Settings: Adjust compression to optimize efficiency and reduce strain on the motor.

4. Peanut Oil Expeller Jamming

Symptoms: The peanut oil expeller screw or press cage gets stuck.

Causes & Solutions:

(1) Foreign Objects: Remove stones or shells from peanuts before feeding them into the peanut oil expeller.

(2) High Moisture Content in Feed: Creates sticky paste hindering clean separation. Use accurate hygrometers to ensure peanuts have the right moisture content.

(3) Residue Build-up: Regularly clean the feed screw and peanut oil expeller to prevent jams.

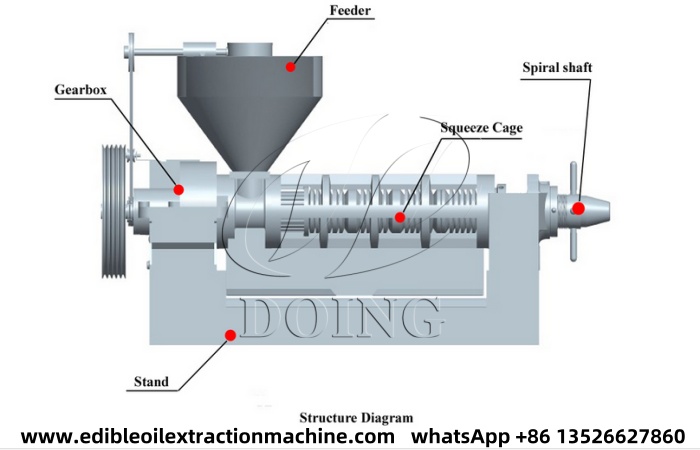

Screw peanut oil expeller

Screw peanut oil expeller

5. Peanut Oil Expeller Overheating

Symptoms: Excessive heat, risking damage to parts.

Causes & Solutions:

(1) Blocked Vents: Ensure proper airflow and clean air vents around the motor.

(2) Excessive Load: Reduce feed rates and pressure to avoid overloading the machine.

(3) Cooling System: Maintain the cooling system to prevent overheating.

6. Slow Processing

Symptoms: Oil extraction is slower than usual.

Causes & Solutions:

(1) Wear and Tear: Regularly inspect and replace worn parts like the screw and bearings.

(2) Leaks: Replace worn seals or gaskets to maintain pressure.

(3) Clogged Oil Channels: Clean oil channels to ensure efficient flow.

Peanut oil expeller parts

Peanut oil expeller parts

7. Inconsistent Oil Extraction

Symptoms: Uneven oil yield between batches.

Causes & Solutions:

(1) Uneven Feed Rate: Maintain a consistent feed rate to ensure uniform extraction.

(2) Compression: Inspect and adjust the peanut oil expeller screw and press cage for even compression.

(3) Peanut Quality: Use uniform-sized peanuts with consistent oil content to avoid variability.

To sum up, by identifying these common peanut oil expeller problems and addressing the root causes, you can improve the efficiency, quality and longevity of your peanut oil expeller. Regular maintenance and monitoring are key to smooth operation and optimal peanut oil production. If you have any questions about peanut oil expeller, please contact Henan Glory Company, which is a manufacturer of specializing in the production and manufacturing of peanut oil expellers for more than ten years!

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line