What are the main process of making rice bran oil?

FAQ / Chat on line / Give me a price / Date:May 17, 2019

Lots of customer who are interested in setting up rice bran oil factory, but they don’t know the rice bran oil making process. The process of making rice bran oil mainly includes 4 workshops. They are separately rice bran pretreatment puffing plant, rice bran oil solvent extraction plant, rice bran oil refinery plant and rice bran oil dewaxing plant.

When you collect rice bran from rice mill factory or market, the first process you need to do is to process the rice bran in rice bran pretreatment puffing plant immediately, so as to make sure the rice bran can reach the best condition for solvent extraction and avoid the rancidity of rice bran. The process of rice bran pretreatment puffing plant that our engineers design inlude four steps, cleaning, conditioning, puffing and drying. Each step has own functions. Cleaning is used to remove impurities in the rice bran, such as stone, broken rice, iron. Conditioning and drying is for adjusting moisture and temperature of rice bran. And rice bran will become to small pellet after puffing, which is better for extract more oil.

Rice bran pretreatment puffing machines

Rice bran pretreatment puffing machines

The next process is rice bran oil solvent extraction. By taking advantage of oil fat and the organic solvents can dissolve with each other, use the n-hexane to react with rice bran to extract crude rice bran oil. It mainly includes solvent extraction system, D.T.D.C system, mixed oil process system and condenser recovery system. Finally you can get two part: One is crude rice bran oil, another is oil cake. Oil residue in the cake is less than 1%. It is suitable used for animal feeding. Crude rice bran oil will be sent to the following rice bran oil refinery plant.

Rice bran oil solvent extraction plant

Rice bran oil solvent extraction plant

Possibly you are curious that I already obtained rice bran oil, and why need rice bran oil refinery plant? Because there are still have invisible impurities in the crude rice bran oil. If you want to get standard cooking oil, rice bran oil refinery plant is necessary for you.

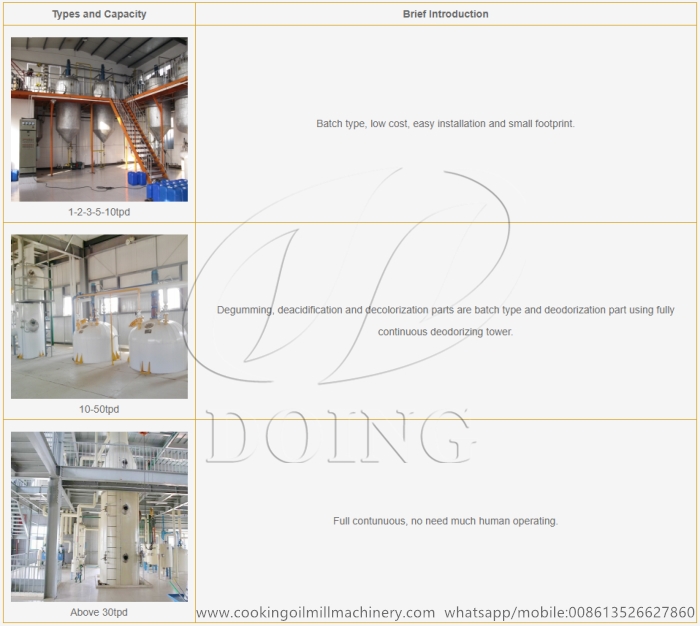

Rice bran oil refinery plant is mainly include degumming, deacidification, decolorization and deodorization. It is used to remove gums, FFA, pigments and bad odors, which aims at improving the rice bran oil storage stability, flavor and color. Then you can obtain stand quality standard cooking oil. Henan Doing Company has different capacity oil refinery plant. They are batch oil refinery plant, semi-continuous and full-continuous oil refinery plant.

Three types of rice bran oil refinery machine

Three types of rice bran oil refinery machine

Finally, rice bran oil will be sent to rice bran oil dewaxing plant to remove wax. Compared peanut oil, soybean oil. the wax content of rice bran oil is high, which is about 1%-5%. Wax will affect oil appearance and make the rice bran oil taste bad. So it is necessary to have rice bran dewaxing plant to produce First Grade rice bran oil. The wax will crystallize and separate from oil when temperature is low. The rice bran oil dewaxing plant mainly includes heating, crystallization and filter three steps.

The four workshops are complete rice bran oil making line. Of course, you can also only choose rice bran pretreatment puffing plant and rice bran oil solvent extraction plant to produce crude rice bran oil. And then sell the crude rice bran oil to oil reinery plant. Henan Doing Company can offer you professional technical support and good quality machines.

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line