Introduction to the complete set of palm oil production line

FAQ / Chat on line / Give me a price / Date:August 10, 2022

The complete set of palm oil production line includes three main sections: palm oil pressing plant, crude palm oil refining plant and refined palm oil fractionation plant. Generally, large scale palm oil production line owns the three sections. Small scale and medium palm oil production line can choose the pressing plant or the pressing and refining plant together. The following is the detailed introduction.

Palm oil pressing plant in palm oil production line: ( palm bunches to crude palm oil )

The palm oil pressing plant in palm oil production line includes 7 machine, including sterilizer, palm fruit threshing machine, digester, palm oil pressers, clarification machine and dryer. The following is the detailed palm oil pressing process.

Palm oil pressing plant

Palm oil pressing plant

Step 1 Sterilization station: Put the fresh palm fruit bunches into sterilization tank. The function of palm fruit sterilization: on the one hand, sterilization can prevent the content of free fatty acids (FFA) from increasing and prevent prevent rancidity. On the other hand, the sterilization makes palm fruit threshing process easier.

Step 2 Threshing station: put the palm fruit into palm fruit threshing machine in order to separate palm fruit from palm bunches.

Step 3 Digesting station: The part is to separate the flesh from kernel and crush the flesh of the palm fruit.

Step 4 Pressing station: The mashed palm fruit is transported to palm oil pressers and though the mechanical extrusion, the crude palm oil is obtained.

Step 5 Oil clarification : The part is to clarify and filter the crude oil from pressing by clarification tank, vibrating screen and plate filter. So we can get the better and cleaner palm oil.

Step 6 vacuum drying : The part is to put the palm oil into the vacuum drying system to evaporate the water in the crude palm oil.

♦For palm oil pressing machine, Henan Glory Company can supply you 500kg/h, 1tph, 5tph, 10tph,15tph capacity. And our engineers can make customized plans according to each customer’s different processing needs.

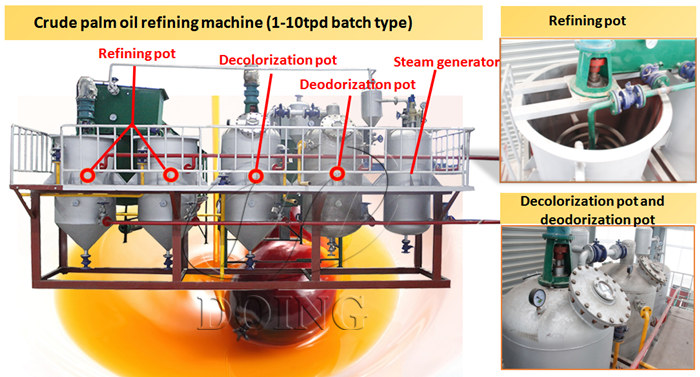

Palm oil refining plant in palm oil production line: ( crude palm oil to refined palm oil )

Palm oil refining plant

Palm oil refining plant

Step 1. Degumming

Generally, crude palm oil has less gum, adding phosphoric acid solution to crude palm oil can make peptized impurities into agglomerates, and the peptized impurities can be removed after sedimentation.

Step 2. Deacidification

Palm oil refining equipment generally uses chemical deacidification to remove free fatty acids, which is to add lye to crude palm oil to neutralize it with free fatty acids. The soap would be formed after neutralizing, which be removed after edimentation, thereby the free fatty acids is removed. So the quality of palm oil is better and the storage time is longer.

Step 3. Decolorization

The specific operation process of decolorization is to add clay to crude palm oil to absorb pigments and other impurities in the oil, and then use the leaf filter to filter out the waste clay in the oil. So the color of palm oil is clearer and is more attractive to palm oil consumer.

Step 4. Deodorization

Deodorization is to inject direct steam into crude palm oil, and take advantage of the difference in volatility between oil and odorous substances to take away odors. After deodorization, the quality of palm oil is improved, and the smoke point and stability are also improved.

♦In the palm oil refining process, the deodorization process needs to be carried out at high temperature, so stainless steel is required. Our engineers of Henan Glory Company strictly abide by the requirements of palm oil refining and use high-quality stainless steel to ensure the smooth development of the refining process.

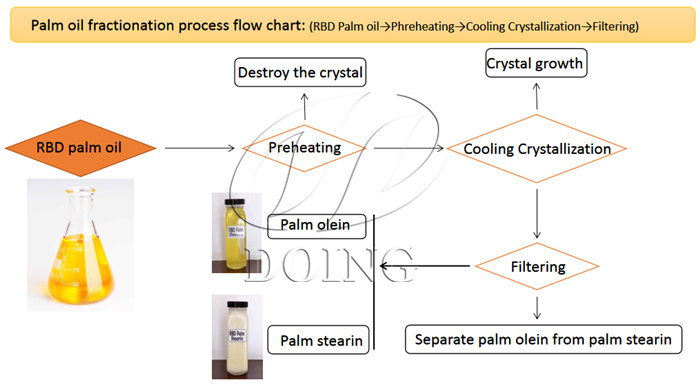

Palm oil fractionation plant in palm oil production line: ( refined palm oil to palm olein, palm stearin )

Palm oil fractionation flow chart

Palm oil fractionation flow chart

Step 1. Heating

The palm oil is heated by a steam heater to destroy the existing crystals and the later crystallization effect is better in this way.

Step 2. Crystal forming

The part is to form crystal by cooling the heated palm oil. The machine used is crystallization tank. By adding cooling water, the palm oil is lowered to the specified temperature, so that the solid oil is precipitated as crystals.

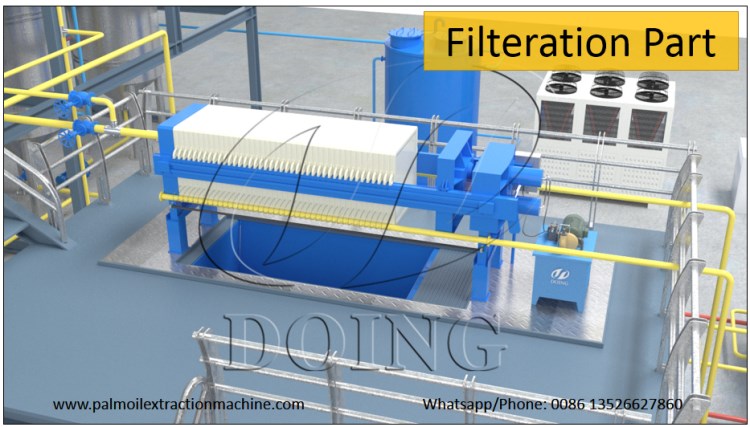

Step 3. Filtering

The palm oil is transported into a membrane filter to separate palm olein and palm stearin. At this point, the palm oil fractionation is completed.

Membrane filter in palm oil fractionation process

Membrane filter in palm oil fractionation process

♦In the palm oil fractionation machine of Henan Glory Company, the hot and cold water can be recycled, reducing waste of resources. The membrane filter used in the filtration process has better filtering effect than the plate filter and leaf filter, and can better separate the palm olein, palm stearin.

If you are interested in palm oil production line, feel free to contact us and we will supply the good-quality equipment and sweet service for you.

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line