How do you manufacture soybean oil?

FAQ / Chat on line / Give me a price / Date:October 18, 2024

The methods to manufacture soybean oil are pressing and solvent extraction. Different production volumes and customer needs require different production lines and manufacturing equipment. If you want to start a soybean oil production business, how to choose soybean oil manufacturing equipment? Next, Henan Glory will give you a detailed introduction to the method to manufacture soybean oil by pressing and solvent extraction method.

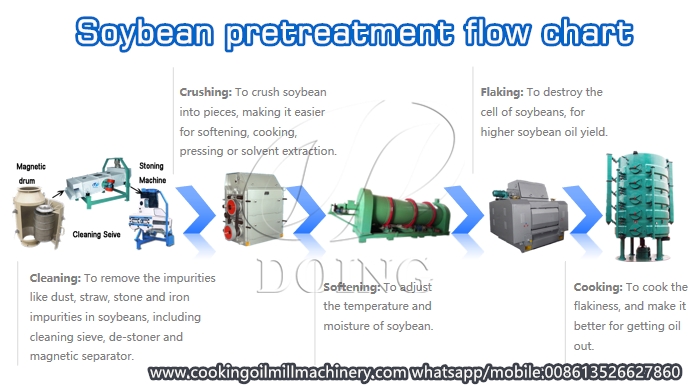

For the method to manufacture soybean oil, whether it is the pressing method or solvent extraction method, the oil must be pretreated. The equipment used to clean impurities mainly includes vibrating screen, destoner and magnetic separator. The raw materials that have not been cleaned contain impurities such as silt, metal, and pebbles, which will affect the subsequent processes. On the one hand, hard metals and stones will affect the normal operation of the machine, and even cause machine failure in serious cases; on the other hand, silt impurities will absorb part of the oil and reduce the oil yield. And because the particle size of soybeans is large, a crusher is needed to reduce the particle size of soybeans. The purpose of this is to increase the surface area, making it easier to extract the soybean oil. Because the oil content of soybeans is low, a softening pot is needed to soften them and increase the moisture content. After that, an flaking roll is used to press the embryos, turning the oil into thin flakes and shortening the oil path.

Pressing method

The price of soybean pressing production line is relatively low, the oil yield is low, and the residual oil rate is 6%-7%. In addition to vibrating screen, destoner, magnetic separator, crusher, softening pot, and flaking roll, a cooker is also needed to manufacture soybean oil. The function of the cooker is to adjust the temperature and moisture of soybeans. After that, it enters the oil press for direct pressing. After pressing, soybean crude oil and cake are obtained. The crude oil will contain fine impurities, so a filter will be used to remove impurities in the crude oil. Finally, we will get a relatively clean soybean crude oil.

Soybean pretreatment machines

Soybean pretreatment machines

Solvent extraction method

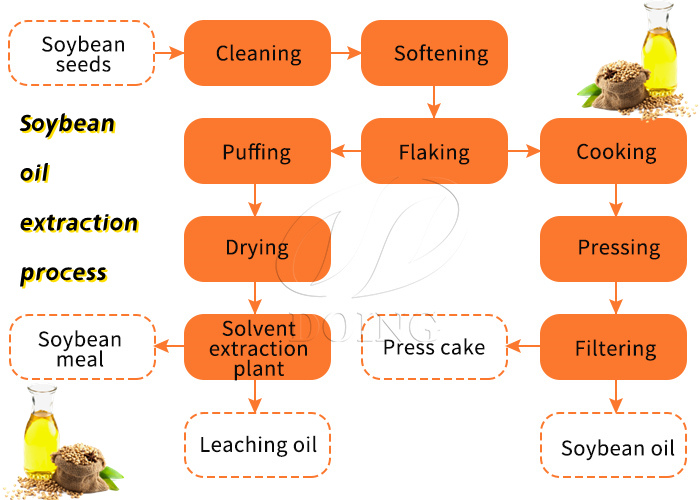

The price of soybean extraction production line is relatively high, the oil yield is high, and the residual oil rate is less than 1%. After pretreatment, The method refers to the use of the miscibility of organic solvents (n-hexane) and oils to extract soybean oil based on the different boiling points of organic solvents and soybean oil. Before extraction, the structure of the oil can be changed with puffing equipment, the structural gap can be increased, and the yield can be increased, and then soybean extraction can be carried out. The main equipment used in this part include extractor, stripping tower, evaporator, oil-water separator, condenser, stripping tower, etc. Soybean extraction oil contains impurities and substances harmful to the human body. It needs to be refined to remove impurities and harmful substances. Henan Glory Company can provide intermittent, semi-continuous and fully continuous soybean oil refining equipment. Besides, we can also match the appropriate soybean oil refining equipment for the customer according to the processing capacity of the soybean oil manufacture plant. Moreover, only refined soybean oils can meet the national stability standards and can be sold on the market.

Soybean oil solvent extraction process flow

Soybean oil solvent extraction process flow

Henan Glory is engaged in the design and manufacturing of soybean oil equipment, selling directly at factory prices. It can provide soybean oil manufacturing equipment with different processing capacities and can customize equipment of different models and processing capacities for customers. If you want to learn more about our equipment or the method to manufacture soybean oil, please feel free to contact us, and we will be happy to serve you!

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line