What equipment are there in edible oil pressing and solvent extraction processes?

FAQ / Chat on line / Give me a price / Date:October 25, 2024

For the equipment for edible oil pressing process, we illustrate by different capacity:

1. The daily processing capacity is less than 5 tons

If the daily processing capacity is less than 5 tons, you can directly use screw oil press machine, which is very simple and easy to operate and has very high pressing efficiency. Or you can use automatic temperature control all-in-one machine, which can automatically adjust the temperature, and with two filter barrels that can help you get cleaner oil. The all-in-one machine has a processing capacity of 1.3 tons to 11 tons per day for your choice.

Edible oil pressing equipment

Edible oil pressing equipment

2. The daily processing capacity is less than 5-10 tons

There are two options for the daily processing capacity of 5-10 tons: one option is the screw oil press machine, and the other is small scale edible oil pressing production line, including pretreatment, press and filter. The oilseed will be very good to get the oil after pretreatment.

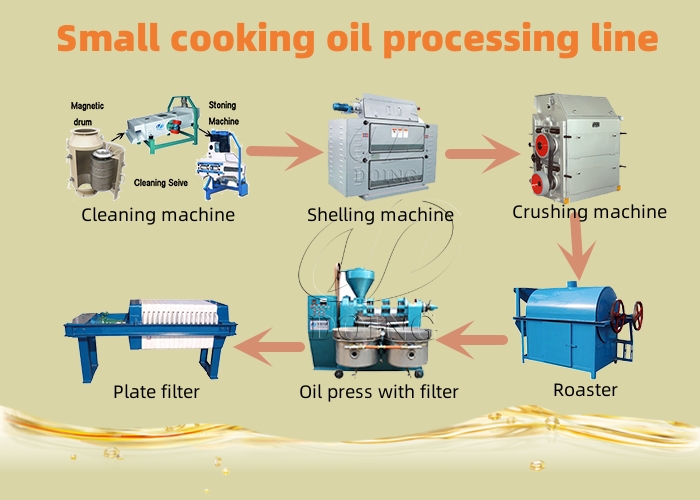

The equipment you need in small scale edible oil pressing production line:

Small scale edible oil processing line

Small scale edible oil processing line

1) Vibrating screen - removes impurities by shaking.

2) Magnetic separator - removes metal impurities from oilseed.

3) Destoner - removes heavy impurities from oilseed.

4) Oil press - Oil press of Henan Glory Company has the characteristics of beautiful appearance, oil extraction effect reaching the national standard, easy operation and low residual oil rate.

5) Filter - The plate filter removes impurities layer by layer and takes away part of the water.

6) Small edible oil refining equipment - through the steps of degumming, deacidification, decolorization, deodorization, etc., the first-grade oil can be sold to the market.

Small scale edible oil refining equipment

Small scale edible oil refining equipment

For the equipment for edible oil solvent extraction process is as following introduction:

The first equipment is the Rotary-type extractor, one of the most important equipment in the whole factory. After 2hours fully mixing the oilseed and the N-hexane, then you will get the oil mixed with solvent we call it miscella and the wet meal.

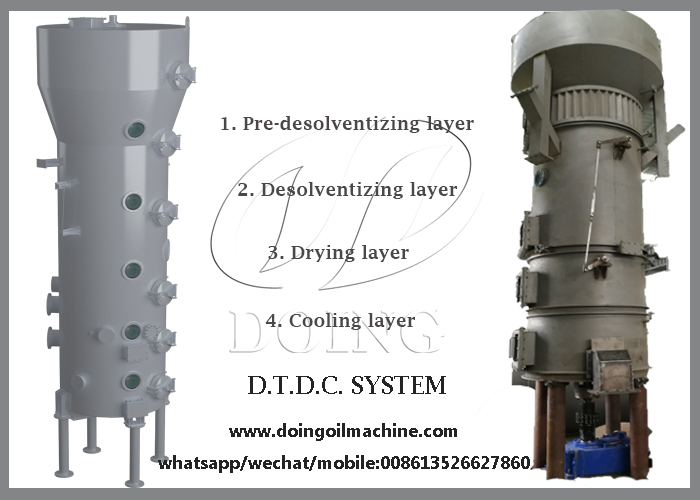

The second equipment is the D.T.D.C--desolventizer-toaster, which is used to remove the solvent from wet meal. The meal including a mount of the solvent about 25%-35%, and the solvent steamed in this part can be recovered and resumed.

D.T.D.C.system

D.T.D.C.system

The third equipment is evaporation system and stripping tower. We use the first evaporator, second evaporator, stripper and other equipment to completely evaporate the solvent from the mixed oil to obtain clean oil.

The last equipment is solvent recovery system, which mainly uses the condenser to convert the gaseous solvent into a liquid state, and uses the water distribution tank to recover the solvent for recycling.

Through solvent extraction method you can get more than 99% oil from oilseed, but the investment is higher than cold and hot press method. And the daily processing capacities must be above 30 tons.

We are Doing Holdings -- Henan Glory Oils & Fats Engineering Co.,Ltd, mainly engaged in edible oil processing equipment design and manufacturering. If you have requirements for edible oil processing equipment, please contact us!

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line