What is dewaxing process during vegetable oil refinery?

FAQ / Chat on line / Give me a price / Date:May 5, 2019

Dewaxing process during vegetable oil refinery is to remove the wax content in some kinds of crude vegetable oil, such as sunflower oil, rice bran oil, cottonseed oil and corn germ oil. Because of high wax content, the quality and flavour of the refined vegetable oil will be influenced. And the presence of wax makes the oil appear cloudy at room temperature. But after dewaxing, the vegetable oil remains clear after 24h of storage at 0˚C.

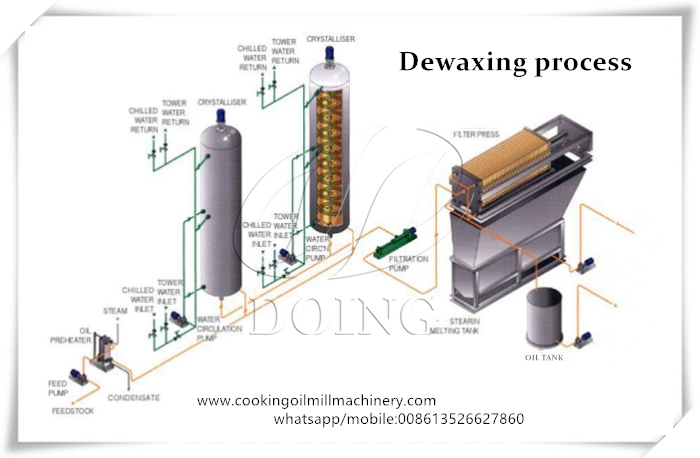

Dewaxing process 3d picture

Dewaxing process 3d picture

So dewaxing process is also called winterization. Henan Doing Company adopts the way of refining first and dewaxing last. So the crude vegetable should be refined in crude vegetable oil refinery plant, and then be pumped into dewaxing workshop. Dewaxing process during vegetable oil refinery has three main steps.

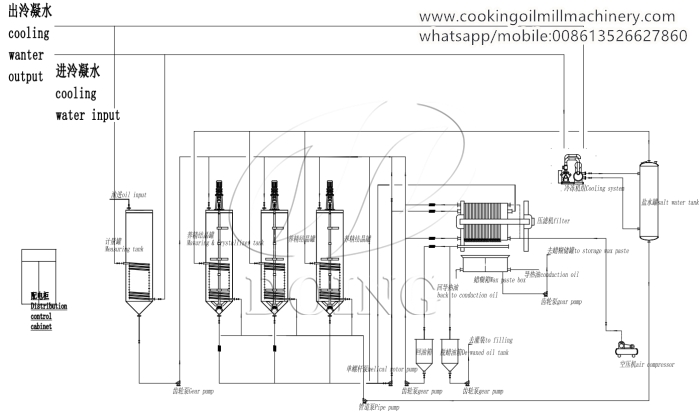

Dewaxing process flow chart

Dewaxing process flow chart

1. First, the refined vegetable oil should be heated to 55˚C, which is to make sure that all the crystal in vegetable oil have been broken.

2. Second, the vegetable oil is cooled slowly to 7–8˚C. In cooling process, new crystal come into being gradually. This process will sustain for 12-24h.

3. At last, after finishing the crystallization, vegetable oil will be pumped into filter machine to separate the wax from vegetable oil.

After dewaxing, the clarity and brightness of vegetable oil are both qualified the national standards. Generally, our customer will buy the sunflower oil refinery plant and sunflower oil dewaxing plant together, in order to get high quality sunflower oil. Henan Doing Company is a professional vegetable oil refinery machine manufacturer. Any question about vegetable oil refining, dewaxing and fractionation, our engineers can give you professional suggestion. Welcome to contact us!

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line