What is cooking oil solvent extraction method? What are the advantages?

FAQ / Chat on line / Give me a price / Date:April 2, 2019

Cooking oil solvent extraction method is a process to extract the oil from oil bearing materials directly or pressed cake by spraying of solvent. Solvent commonly adopted in cooking oil industry is normal hexane – a kind of petroleum bye product. Through cooking oil solvent extraction method, the residual oil rate can be less than 1%. In other words, you can get more oil than using pressing method.

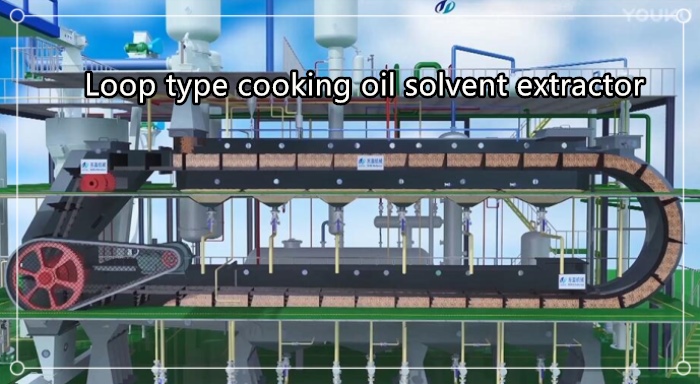

The loop type cooking oil solvent extractor

The loop type cooking oil solvent extractor

When to choose cooking oil solvent extraction method to extract oil? Usually, cooking oil solvent extraction method suits for large oil seeds feeding capacity, like 30 tons per day or more than 30 tons per day. Except the oil seeds feeding amount per day, another factor affecting you whether choose cooking oil solvent extraction method or not is which kind of oil seed you plan to process. Because the oil content in different oil seeds is totally different, and even, the oil content of same oil seed is also different among different country or area among the whole word.

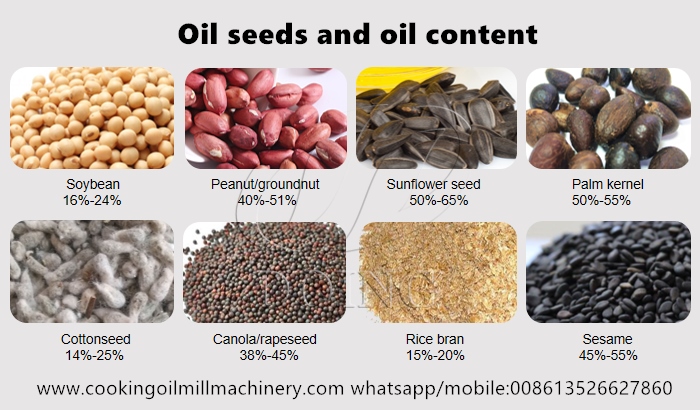

The oil content of oil seeds as following picture shows:

As the above picture shows, it is obvious that peanut, palm kernel, sunflower seed, sesame belong to high oil content oil seeds, while like soya bean, rice bran belong to low oil content oil seeds. These two kind oil seeds have different process in cooking oil making process. The former uses pretreatment, pre-pressing and solventextraction process, and the later adopts pretreatment and solvent extraction directly process.

So if your raw oil seed belongs to high oil content materials, you will get one part of oil from cooking oil pre-press machine and another part oil will be extracted out in cooking oil solvent extraction plant. If your raw oil seed belongs to low oil content materials, the oil you got is all from cooking oil solvent extraction plant. Among the processing, pretreatment section aims to meet the requirements and best condition before solvent extraction processing, which will be much easier for extracting oil by cooking oil solvent extraction method.

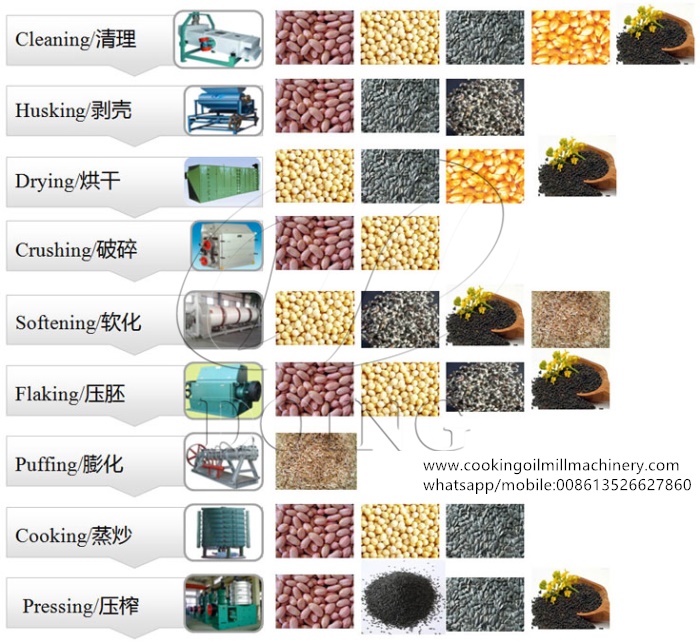

Oil seeds pretreatment equipment and cooking oil press machine

Oil seeds pretreatment equipment and cooking oil press machine

But the pretreatment line in above picture is not all required during pretreatment. Which machine and how many machines are needed during pretreatment depend on your raw oil seed. Like sunflower seed, cotton seed, peanut /groundnut need shelling and separating kernels from shells after cleaning section, while soybean doesn’t. And rice bran need puffing machine while other oil seeds doesn’t.

The main equipment used in cooking oil solvent extraction plant

The main equipment used in cooking oil solvent extraction plant

After pretreatment or pre-pressing, oil seeds or oil cakes will be sent into cooking oil solvent extraction plant. Four parts are included in cooking oil solvent extraction process.

Solvent extraction process to get micella and wet meal;

Micella evaporation process to remove the solvent in micella;

C. Wet meal desolventizing process to remove the solvent in wet meal, also called DTDC system (Desolventizer-Toaster-Drier-Cooler);

D. Condensation recovery process to recover solvent and recycle.

What advantage does choosing cooking oil solvent extraction method to extract oil have?

High oil yield, final residual oil is only less than 1%, and extract as much as possible oil from oil seeds or oil cakes compared with mechanical pressing method. Improve the economic efficiency of enterprises.

2.High level of automation, low processing cost, low labor strength.

3.High quality of meal, the residual oil in meal is little, more suit for animal feed.

In conclusion, if you want to use cooking oil solvent extraction method to making cooking oil, the capacity feeding is better more than 30 tons per day. Then tell us what oil seed you want to process,our engineers will design for you based on your total budget. Henan Doing Mechanical Equipment Co,.Ltd will guide you to set up a cooking oil factory step by step.

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line