Home>Blog>Which one is better for extracting cooking oil by pressing method or solvent extraction method?

Home>Blog>Which one is better for extracting cooking oil by pressing method or solvent extraction method?

Which one is better for extracting cooking oil by pressing method or solvent extraction method?

FAQ / Chat on line / Give me a price / Date:July 23, 2022

For cooking oil processing methods, there are two methods which are cooking oil pressing method, cooking oil solvent extraction method. which one is better? We can’t answer the question because we can’t decide to choose the processing method and the specific equipment when not knowing the features and oil content of oils and needs for cooking oil production in reality.

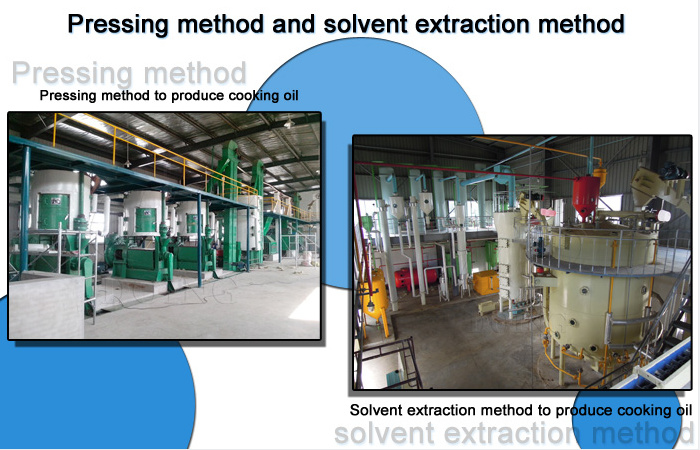

Cooking oil pressing method and cooking oil solvent extraction method

Cooking oil pressing method and cooking oil solvent extraction method

The cooking oil pressing and solvent extraction process have their own advantages, and it is only necessary to select the corresponding processing equipment according to the raw materials and needs for cooking oil production line.(Recommend reading:Sunflower oil processing plant)

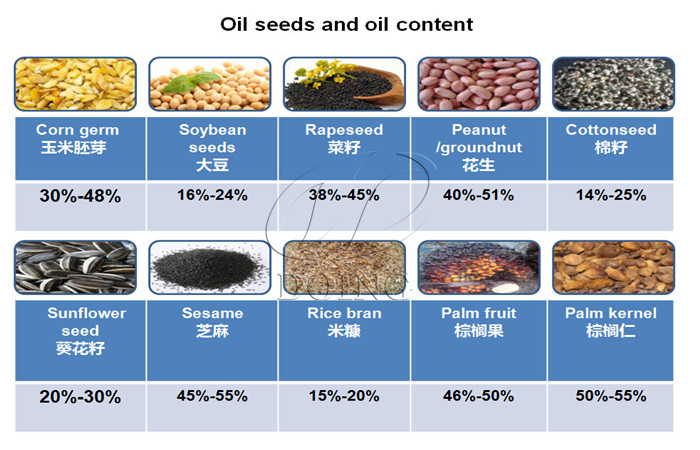

Oil seeds and oil content

Oil seeds and oil content

It is recommended to adopt the pressing method for high oil content oils (rapeseed, sesame, peanut).(Related reading:Cooking oil press production line, machine and project short video)

Cooking oil pressing production line

Cooking oil pressing production line

Reason one: The pressing method adopts the extrusion method to extract oil according to the characteristics of the oil. The pressing process completely belong to physical processing technology and does not add any chemical substances, so that the pressed oil not only retains its color and pure fragrance, but also reduces the loss of nutrients and owns high nutritional value.

Reason two: For oil with high oil content, the residual oil rate in the oil cake can be reduced to 6% to 7% by the pressing method. Most of the oil has been extracted, and the remaining residual oil is negligible. Therefore, extracting high oil content oil by the pressing method is quite feasible.

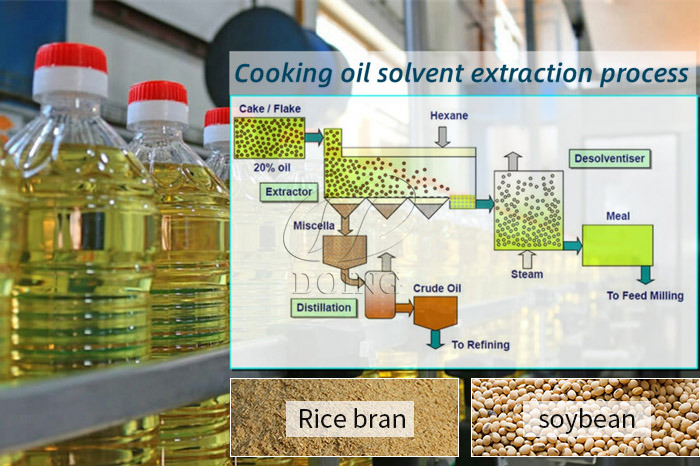

It is recommended to adopt the solvent extraction method for low oil content oils ( soybean, rice bran ).(Related reading:Edible oil solvent extraction plant video with real project running video)

Cooking oil solvent extraction process

Cooking oil solvent extraction process

Reason one: The solvent extraction method adopts principles of chemical extraction to extract oil. Solvent extraction can fully extract oil from raw materials but pressing method can’t realize. The residual oil rate is 5%-8% by the pressing method. But,using the solvent extraction method to make oil, the residual oil rate can be below 1%.

Reason two: Compared with the oil production by pressing, the production of oil by solvent extraction can obtain the better quality of the meal because the operating temperature of the relevant process is relatively low, which adds feed value and helps to extract vegetable protein from the meal.

Reason three: Compared with the oil-pressing method, the production line used in the solvent extraction is generally more complete and owns high automation. Besides, the solvent extraction workshop has few operators and low labor.

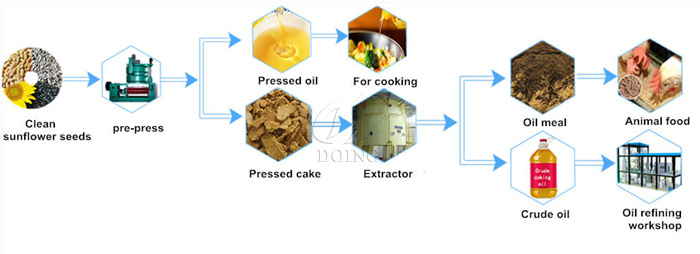

Besides, the cooking oil pressing process and the solvent extraction can be used together. For example, for high oil content oil, like, sunflower seed, rapeseed, sesame, peanut, people usually adopt pre-pressing and solvent extraction together. The method can realize the residual oil rate in the cake is reduced to less than 1%. Especially for large-scale cooking oil processing factories, profits can be maximized.

Cooking oil pressing process and the solvent extraction can be used together

Cooking oil pressing process and the solvent extraction can be used together

Therefore, the cooking oil pressing process and the cooking oil solvent extraction process are just different oil processing methods, which are not directly related to the quality of the final oil product. As long as the appropriate cooking oil processing equipment is selected according to the characteristics of the oil.

As a professional manufacturer of cooking oil processing machine, Henan Glory Company has built a 20,000-square-meter cooking oil processing equipment manufacturing plant and professional technical research and development team, equipment manufacturing team. If any questions about cooking oil processing technology and cooking oil processing machine, feel free to contact us.

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line