What is sunflower oil processing steps in plant?

FAQ / Chat on line / Give me a price / Date:June 10, 2019

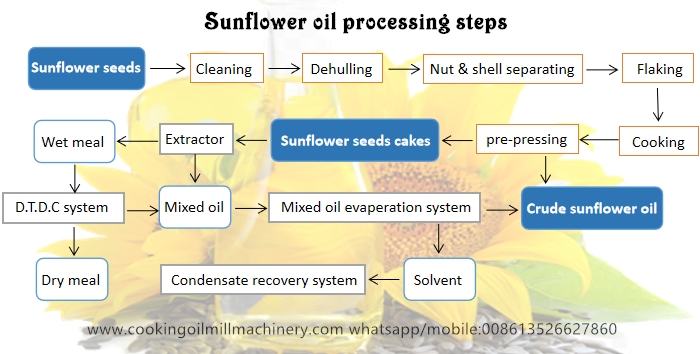

The sunflower oil processing steps in large scale sunflower oil processing plant

The sunflower oil processing steps in large scale sunflower oil processing plant

As the above picture shows, the sunflower oil processing steps contains cleaning, husking, flaking, cooking, pressing and filtering. Even though presser is the most important equipment in sunflower oil processing plant, the pretreatment equipment are also vital in the whole sunflower oil processing steps. As almost all the pressers' residual oil rate is in the range 5%-11%, only through these pretreatment steps, such as the cleaning, flaking, cooking, can decrease the residual oil in cake.

The machines used in sunflower seeds pretreatment and pressing plant

The machines used in sunflower seeds pretreatment and pressing plant

Another sunflower oil extraction way, solvent extraction method could let the residual oil rate lower than 1%. No matter what extraction method you choose, the pretreatment is the necessary in the whole sunflower oil processing steps. Why it is so important? We, Doing Mechanical Equipment Co.,ltd made much researches according to our customers' actual situation.

Most of customers buy sunflower seeds from farmers. There are more or less impurities mixed with sunflower seeds, like stones, sand, metal impurities and others. These sand impurities will still remain in machines and oil after pressing. As for stone and metal impurities will damage machines, and decrease the useful life of machines. In order to get rid of those impurities, cleaning machine is needed before pressing or solvent extraction.

Three types of cleaning machine used in sunflower oil processing steps

Three types of cleaning machine used in sunflower oil processing steps

After cleaning, the shells of sunflower seeds can be removed by husking machine. But the sunflower seeds husking machine is a little expensive, so only in large scale sunflower oil processing plant, they will equipped the sunflower seeds husking machine. In small scale or medium scale sunflower oil processing plant, they generally choose to press sunflower seeds with shells.

Falking machine and cooking machine used in sunflower oil processing steps

Falking machine and cooking machine used in sunflower oil processing steps

Flaking is to make sunflower seeds into small piece, so as to press much easily and prepare well for cooking step. Then, cooking machine is in order to adjust sunflower seed moisture content and temperature before pressing. Only reach the needed temperature and humidity, the oil yield could be higher.

The prepresser and solvent extractor used in large scale sunflowe roil processing plant

The prepresser and solvent extractor used in large scale sunflowe roil processing plant

The cooked seed can be pressed by sunflower oil press machine, also can be sent to the sunflower oil solvent extraction plant. If you has large quantities of raw materials--sunflower seeds, in order to decrease oil residue, our engineers of Henan Doing Company will recommend you to adopt prepressed and solvent extraction combined way to get more oil. Because the oil content of sunflower seeds is very high, and after pressing, the residual oil in the cake is still much.

What we discussed above is the whole sunflower oil processing steps in large scale sunflower oil processing plant. If you want to start sunfower oil business, you can send us your needs. If you want to start with a mini capacity, we recommend you a set of cooker and all-in-one unit presser.

Cooker and all-in-one unit presser used in small sunflower oil mill

Cooker and all-in-one unit presser used in small sunflower oil mill

Welcome your asking and Doing Company will provide you technology explaination, machine list and quotation.

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.