Canola oil processing plant

Canola oil processing plant / Chat on line / Give me a price

Rape flower and canola seeds

Rape flower and canola seeds

Canola seed is a high oil content oilseed, which can reach about 39%-48%. The main producing countries is China, Canada, India, European community and so on. Thus lots of people are interested in setting up canola oil processing factory.

Every customer has their own requirements for building a canola oil processing factory. According to customer's needs for processing canola seeds amount per day, Henan Doing Company provides different suggesstions of technology process.

Some suggestions are as following for customer reference:

| Raw material | Processing canola seeds amount per day | Suggesstions of technology process |

| Canola seeds | 1-10tpd | Screw oil press machine |

| 20-50tpd | Canola seeds pretreatment & pressing plant | |

| 50-1000tpd | Canola seeds pretreatment & pre-pressing & solvent extraction plant | |

| Crude canola oil | 1-20tpd | Batch type canola oil refinery plant |

| 20-50tpd | Semi-continuous canola oil refinery plant | |

| 50-600tpd | Full-continuous canola oil refinery plant |

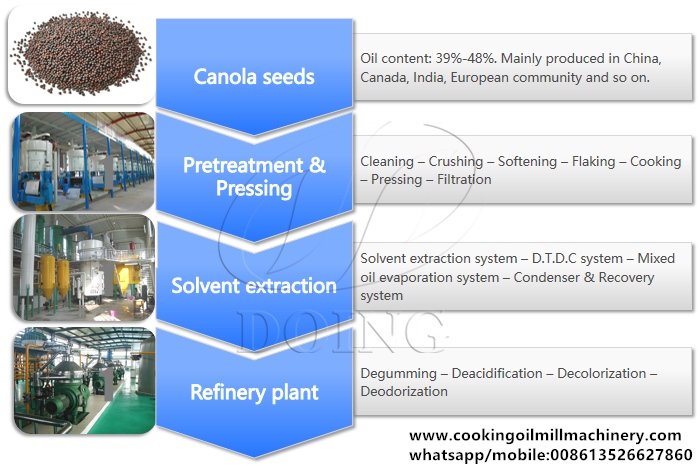

The complete canola seed oil production line mainly includes three workshop: Canola seeds pretreatment pressing plant, canola oil cake solvent extraction plant and canola oil refinery plant. You can choose one of them or all of them to set up a canola oil processing factory.

The complete canola oil production line

The complete canola oil production line

The first step is canola seeds pretreatment & pressing plant, mainly including cleaning, crushing, softening, flaking, cooking, pressing, filtering. Finally, you get crude canola oil and oil cakes.

The canola oil pretreatment & pressing machines and working process flow chart

The canola oil pretreatment & pressing machines and working process flow chart

The second step is canola oil cake solvent extraction plant, mainly including solvent extraction system – D.T.D.C system – Mixed oil evaporation system – Condenser & Recovery system. Finally, the oil residue can be less than 1%.

The equipment in canola oil solvent extraction plant

The equipment in canola oil solvent extraction plant

The third step is canola oil refinery plant, which is to refine crude canola oil into refined canola oil. Through degumming, deacidification, decolorization and deodorization process, remove impurities in the crude canola oil, such as gums, FFA, pigment, bad odors, etc. Aims at improving the canola oil storage stability, flavor and color, to get standard quality edible oil.

Canola oil refinery plant has three types, as the following picture shows:

Three types canola oil refinery plant

Three types canola oil refinery plant

The brief introduction of canola oil processing plant is all. Tell us your canola seed amount you want to process per day, and our engineers design for you and give you the best quotation. Welcome to leave your message!

Related product recommend

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.